LiftMaster APT APT LOGIC 3 Manual - Page 26

Troubleshooting Guide

|

View all LiftMaster APT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

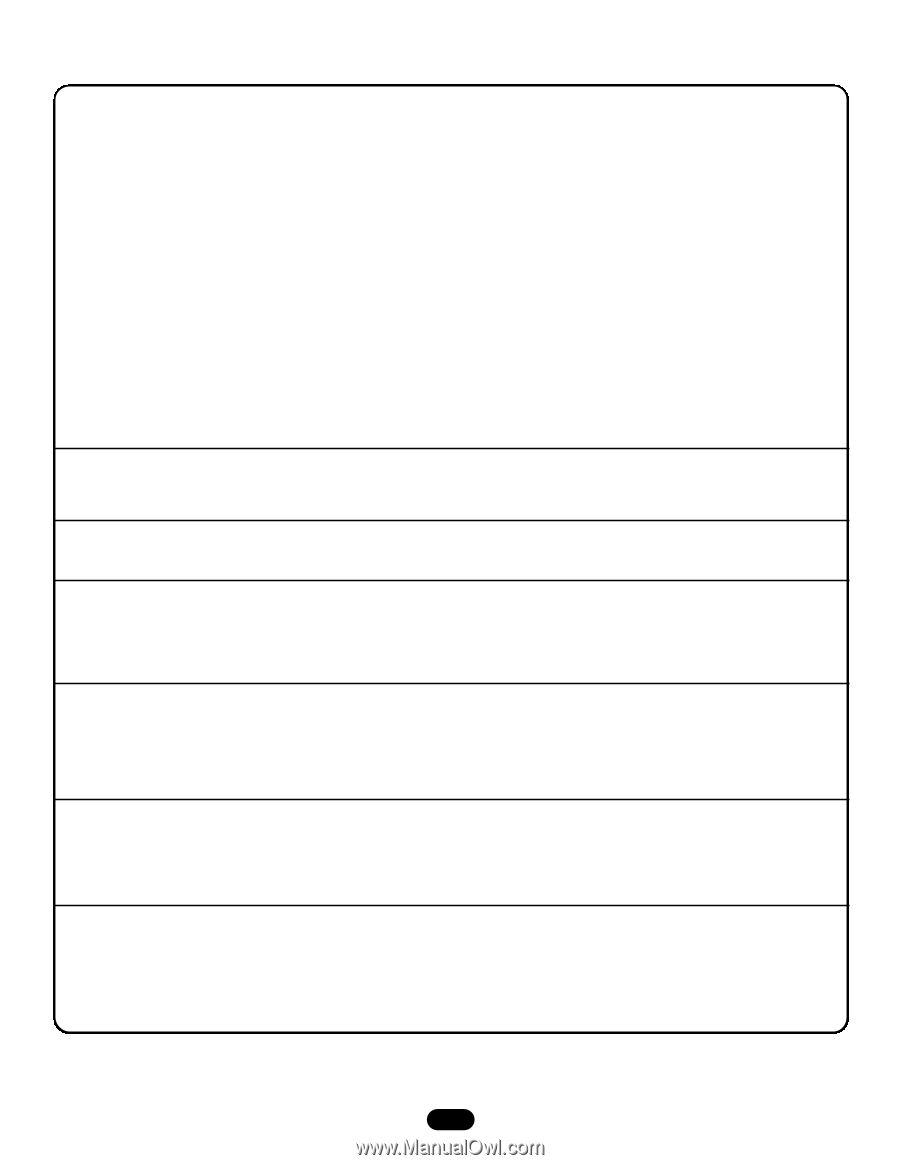

TROUBLESHOOTING GUIDE FAULT THE OPERATOR WILL NOT RESPOND TO ANY COMMANDS POSSIBLE CAUSE FIX a) No power supply b) Operator control station is wired wrong c) Interlock switch is activated d) Dial still in programming or diagnostic mode e) Motor is malfunctioning f) Motor thermal overload tripped g) Failsafe switch is activated requiring photo eyes h) Off Board relay may need to be replaced see wiring diagram i) Possible accessory malfunction j) Possible logic board failure ➤ Verify primary line voltage from power source. ➤ Use the OPEN, CLOSE and STOP LEDs to help check correct wiring. Verify that the board is accepting commands by using the onboard station. Green light next to stop button must be on. ➤ Check Interlock(s). If more than one external interlock is present they must be wired in series. ➤ Set dial to desired wiring type. ➤ Verify proper voltage getting to the motor (Check motor name plate). ➤ Check for obstructions and verify the door moves freely. Cycle operator in constant pressure one full cycle open and close to reset fault. Check to see if motor is hot. Allow motor to cool before attempting to move door. ➤ Move switch to non-failsafe or connect a failsafe sensing device. ➤ When the OPEN or CLOSE button is pressed, Relay A or B LED should turn on and the door should move in the corresponding direction. If Relay A or B lights and the door does not move, off board relay may need to be replaced (see wiring diagram Off Board Relays). ➤ Disconnect all devices, reattach them one at a time testing for a failure after each one is replaced. ➤ Replace logic board. POWER LED IS NOT ON a) Loose secondary wiring connections or a faulty control transformer b) Logic board failure c) Interlock switch ➤ Repair or replace connections or control transformer. ➤ Replace logic board. ➤ Check interlock(s). STOP BUTTON LED IS NOT ON a) Control station not connected or wired ➤ Check wiring to control station. correctly b) Interlock switch ➤ Check interlock switch(es) for continuity. THE DOOR WILL MOVE ABOUT A FOOT THEN STOP. AFTER STOPPING, ONLY CONSTANT PRESSURE COMMANDS WILL MOVE THE DOOR RPM sensor is not connected properly or may need to be replaced ➤ Check the RPM assembly for loose connections. Check that RPM wheel is turning when operator is running. Check for foreign matter blocking optical lens. ➤ Replace RPM sensor. THE DOOR WILL MOVE MOST OF THE WAY TOWARDS A LIMIT THEN STOP. AN EXTRA OPEN OR CLOSE COMMAND IS ABLE TO GET DOOR TO COMPLETE CYCLE The Maximum Run Timer is not set correctly ➤ Manually reprogram the Maximum Run Timer (page 24). OR reset the factory defaults (page 25). THE DOOR WILL OPEN SOME BUT NOT COMPLETELY. AN EXTRA OPEN IS ABLE TO GET THE DOOR TO OPEN COMPLETELY There may be a Mid Stop set ➤ Check to see if the Mid Stop LED is on. Clear the Mid Stop by turning the selector dial to program. Press and hold the MID STOP button for 5 seconds. Return dial to desired wiring type. THE DOOR WILL OPEN BUT a) The photo eyes, edge or other sensing WILL ONLY CLOSE AFTER device is obstructed or activated A FIVE SECOND DELAY WITH CONSTANT b) The logic board thinks that the direct PRESSURE ON THE CLOSE connect photo eyes are attached and BUTTON blocked c) Failsafe switch set ➤ If the on board EYES LED is flashing, the photo eyes are misaligned or not connected. Remove any obstructions, check the safety device wires for continuity and shorts. ➤ Unlearn the photo eyes from the memory by resetting factory defaults. ➤ Slide switch to Non-Failsafe mode. 26