LiftMaster APT APT LOGIC 3 Manual - Page 27

Troubleshooting Error Codes

|

View all LiftMaster APT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

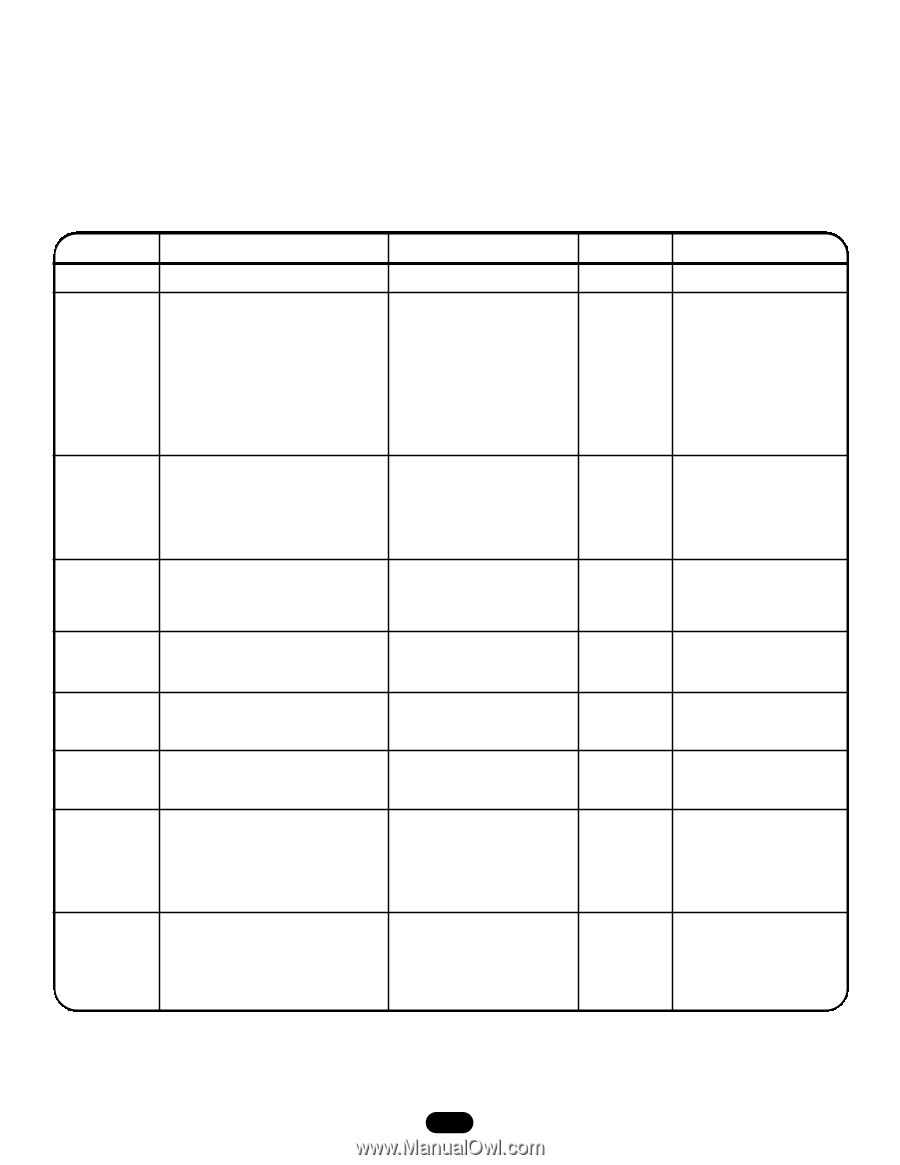

TROUBLESHOOTING ERROR CODES Logic 3.0 operators incorporate a self diagnostic feature built into the MAS LED. In addition to indicating when routing maintenance is due, the MAS LED can be used to troubleshoot some problems with the operator. If the MAS LED is flashing on and off rapidly, the Maintenance Alert System has been triggered and the schedule operator service is due. If the MAS LED flashes 2 or more pulses in a row followed by a pause, an operator error has occurred. To view how many errors currently exist, turn the selector dial to DIAGNOSTIC and press the OPEN button. To read out each individual error code (if more than one exists) press CLOSE. It is possible to have more than one error at a time. The chart below can assist with identifying the flashes on the MAS LED. ERROR CODE DESCRIPTION EFFECT E1 MAS triggered (cycles or months) None normal operation E2 No RPM input during opening or closing The door only responds to constant pressure commands DISPLAY 1 blink 2 blinks E3 (MRT) Maximum Run Time timed out The door stops before reaching 3 blinks the desired time E4 Obstruction sensed on closing Operator will be in the OPEN position 4 blinks E5 Stuck key button pressed for greater than Stuck key on 3-button station 5 blinks 2 minutes. will not respond E6 Rotary dial in invalid position for greater The door will not respond to 6 blinks than 30 seconds. the 3-button station or any other input E7 Failsafe Safety device faulted or not Normal operation (5 second connected for greater than 2 minutes constant pressure override required to close) 7 blinks E8 Brownout Detected Operator will run as long as enough power is present 8 blinks E9 Motor movement at invalid time Operator will continue to Flash on start function normally for 5 operations of movement and then default to a constant pressure mode. CORRECTION Reset MAS. Clutch is slipping, adjust clutch, or verify RPM sensor connection or replace RPM sensor. NOTE: To relearn the RPM sensor, move the door with a constant pressure command. The door will stop once relearned and normal operation will resume. First check Operator for any faults (i.e., Bad Limit switch), manually learn Max Run Timer (see page 23) OR reset factory defaults (see page 24). Cleared by removing obstruction or realigning photo eyes and giving a close command. Stuck key must be unstuck before it will be recognized as an input. Rotary dial must be set to a valid position. Cleared when safety device is cleared or connected. 1. Check AC line for voltage. 2. Check transformer secondary for low voltage. To many accessories may be connected to the transformer. Check relays and the drive circuitry to insure that they are turning off. Operator must run correctly for two starts for the error to be cleared. NOTES: Error codes take priority over normal MAS LED operation. Error codes will repeat on the MAS every 1.5 seconds until cleared. There may be more than one error present, but only the highest priority will flash. If the highest error is cleared, the next highest will flash. All errors self-correct when the corrective action is taken and a reset is not needed. 27