Tanaka TED-270PFDH Owner's Manual - Page 7

Assembly procedures, Operating procedures

|

View all Tanaka TED-270PFDH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

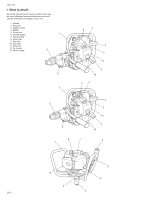

TED-270 Fig.1-1 Fig.1-1B Fig.1-1C Fig.1-1D Fig.2-1 3. Assembly procedures Assembling (Fig. 1-1, 1B, 1C) 1. Assemble the handle (1) witch is supplied with the unit to the gear case. 2. Screw the chuck unit (2) into the drive shaft (clockwise) after the collar B (3) has been installed. (if so equipped) 3. Insert the drill bit to be used after opening the chuck by the chuck handle (4) and tighten the chuck by the handle. NOTE! If the keylesschuck is equipped, loosen chuck and insert drill bit. Then tighten chuck by turning clockwise till making "click" noise (Fig.1-1D) Selection of a Suitable Bit Choose a drill bit according to material to be drilled. 4. Operating procedures Fueling Fuel (Fig. 2-1) WARNING! The power drill is equipped with a twostroke engine. Always run the engine on fuel, which is mixed with oil. Provide good ventilation, when fueling or handling fuel. WARNING! Always shut off the engine before refueling. Slowly open the fuel tank, when filling up with fuel, so that possible over-pressure disappears. Tighten the fuel cap carefully, after fueling. Always move the unit at least 3 m (10 ft.) from the fueling area before starting. Fuel Always use branded 89 octane unleaded gasoline. Use genuine two-cycle oil or use a mix between 25:1 to 50:1, please consult the oil bottle for the ratio or Tanaka dealer Only for the state of California at 50:1. If genuine oil is not available, use an antioxidant added quality oil expressly labeled for air-cooled 2-cycle engine use(JASO FC GRADE OIL or ISO EGC GRADE). Do not use BIA or TCW (2-stroke water-cooling type) mixed oil. Never use multi-grade oil (10 W/30) or waste oil. Always mix fuel and oil in a separate clean container. Before fueling, clean the tank cap area carefully, to ensure that no dirt falls into the tank. Make sure that the fuel is well mixed by shaking the container, before fueling. Always start by filling half the amount of fuel, which is to be used. Then add the whole amount of oil. Mix (shake) the fuel mixture. Add the remaining amount of fuel. Mix (shake) the fuel-mix thoroughly before filling the fuel tank. GB-6