Brother International CB3-B917 Service Manual - Page 36

Brother International CB3-B917 Manual

|

View all Brother International CB3-B917 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 36 highlights

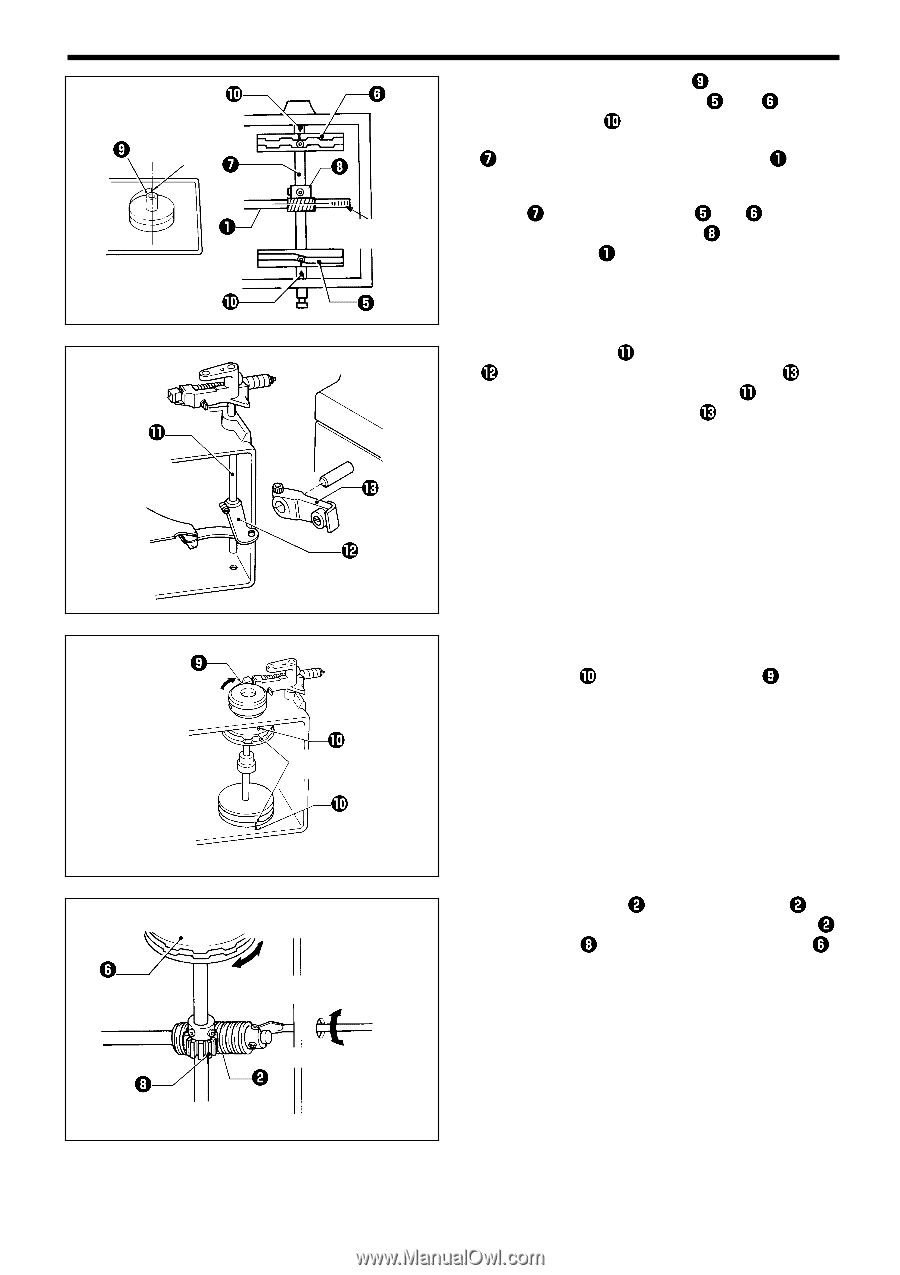

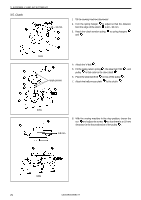

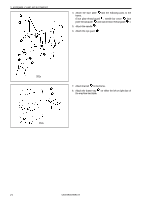

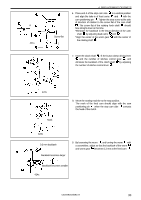

A 421s Screw flat 4. REPLACEMENT OF PARTS 6. Place end A of the stop cam side in a vertical position and align the take-in of feed cams and with the cam positioning pin . Tighten the stop screw at the side of direction of rotation to the screw flat of the cam shaft . The screw flat of the rotating hook shaft face straight down at this time. should *Eliminate the backlash in the thrust direction of the cam shaft by adjusting feed cams and . *Align the center of the worm gear with the center of the rotating shaft . 7. Insert the clutch shaft , fit the button clamp driving lever and the number of stitches control lever , and eliminate the backlash of the clutch shaft by adjusting the number of stitches control lever . 422s Mark 8. Move the sewing machine to the stop position. The mark of the feed cam should align with the cam positioning pin when the stop cam side contacts the head of the clutch. 423s 0.3 mm backlash Backlash becomes larger 9. By loosening the worm , and turning the worm with a screwdriver, adjust so that the backlash of the worm and worm gear becomes 0.3 mm at the feed cam . Backlash becomes smaller 424s CB3-B916A/B917A 30