Brother International CB3-B917 Service Manual - Page 43

Worm and worm gear backlash, 13.Pulley clearance in thrust direction, 14.Slider, B917A, B916A

|

View all Brother International CB3-B917 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 43 highlights

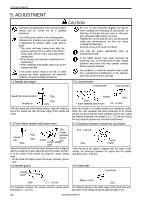

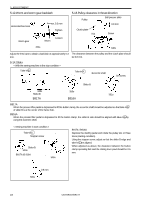

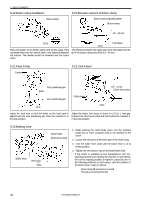

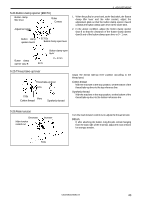

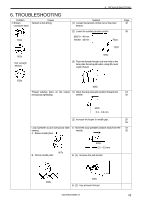

5. ADJUSTMENT 5-12.Worm and worm gear backlash Horizontal feed cam Worm gear Approx. 0.3 mm Tighten Worm Loosen 5-13.Pulley clearance in thrust direction Pulley Ball presser plate 0.8 mm Clutch plate Nut Screw 424s 346s Adjust the feed cam to obtain a backlash of approximately 0.3 The clearance between the pulley and the clutch plate should mm. be 0.8 mm. 5-14.Slider < With the sewing machine in the stop condition > Take-in B Take-in A Eccentric shaft Set screw Slider B 349s Slider B 350s 351s B917A B916A B917A When the presser lifter pedal is depressed to lift the button clamp, the eccentric shaft should be adjusted so that take-in B of slider B is at the center of the frame hole. B916A When the presser lifter pedal is depressed to lift the button clamp, the slider B side should be aligned with take-in A by using the eccentric shaft. < Sewing machine in start condition > Take-in C Stopper screw Slider B 504s B917A /B 916A 505s B917A / B916A Depress the starting pedal and rotate the pulley two or three times (starting condition). Using the stopper screw, adjust so that the slider B edge and take-in C are aligned. When adjusted as above, the clearance between the button clamp operating fork and the driving lever pawl should be 0.6 mm. 506s 0.6 mm 37 CB3-B916A/B917A