Brother International CB3-B917 Service Manual - Page 54

heavy thread.

|

View all Brother International CB3-B917 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 54 highlights

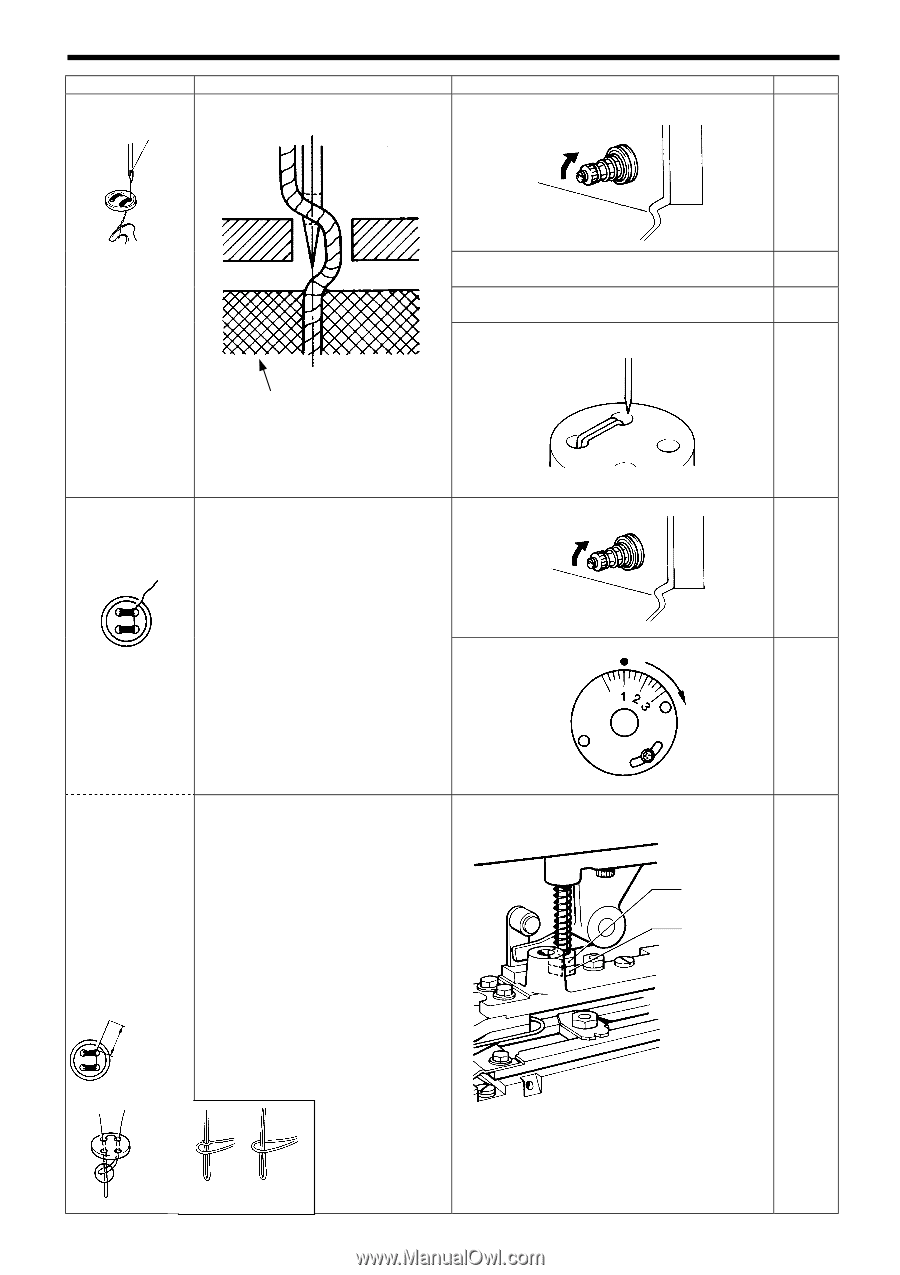

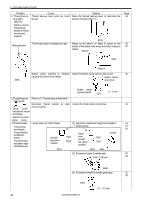

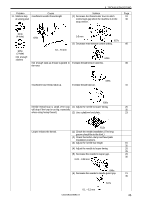

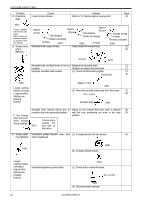

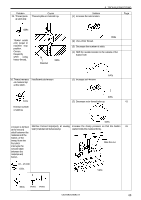

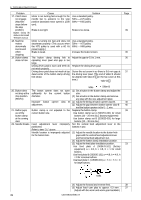

Problem 15. Thread parts at stitch link Cause Thread splits on material top. 639s • Thread winds onto looper in machine stop position. • Occurs frequently when using heavy thread. Material 608s Solution (1) Increase the sub tension. 6. TROUBLESHOOTING Page (2) Use a finer thread. 606s (3) Decrease the number of stitch. (4) Shift the needle location to the outside of the button hole. 16. Thread remains Insufficient sub tension on material top at first stitch. (1) Increase sub tension. 640s 641s • Normal number of stitches 606s (2) Decrease rotor thread take-up. 41 619s A looper is formed Stitches formed improperly at sewing Increase the clamp pressure so that the button 41 at the second start (material not fed properly). clamp holds the material firmly. stitch between the material and the button, or the thread from the first stitch Rise the nut interrupts the second stitch between the material and button. 10 - 15 mm 642s 523s 643s 64302s 64303s CB3-B916A/B917A 48