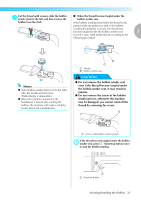

Brother International PE500 Users Manual - English - Page 35

the bobbin winder seat. It may result

|

View all Brother International PE500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 35 highlights

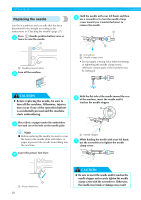

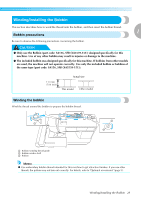

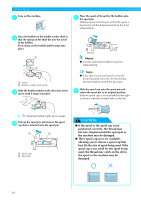

Cut the thread with scissors, slide the bobbin n winder shaft to the left, and then remove the ■ When the thread became tangled under the bobbin winder seat. bobbin from the shaft. If the bobbin winding starts when the thread is not passed under the pretension disk of the bobbin- winding thread guide correctly, the thread may become tangled under the bobbin winder seat. 1 In such a case, wind off the thread according to the following procedure. Memo z If the bobbin winder shaft is set to the right side, the needle will not move. (Embroidering is impossible.) z When the machine is started or the handwheel is turned after winding the bobbin, the machine will make a clicking sound; this is not a malfunction. b a a Thread b Bobbin winder seat CAUTION ● Do not remove the bobbin winder seat even if the thread become tangled under the bobbin winder seat. It may result in injuries. ● Do not remove the screw of the bobbin winder presser, otherwise the machine may be damaged; you cannot wind off the thread by removing the screw. a a Screw of the bobbin winder presser If the thread become tangled under the bobbin a winder seat, press (Start/stop button) once to stop the bobbin winding. a a Start/stop button Winding/Installing the Bobbin 33