Brother International PE500 Users Manual - English - Page 66

Adjusting the bobbin thread, tension

|

View all Brother International PE500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 66 highlights

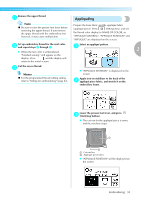

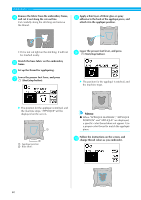

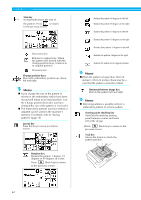

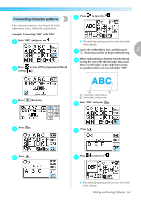

EMBROIDERY Adjusting the bobbin thread tension The bobbin case installed in this machine can be adjusted, if necessary, to accommodate the bobbin tension for embroidering. Using a small slotted screwdriver, turn the slottedhead (-) screw to adjust the bobbin case tension. 1 2 a Do not turn a phillips screw (+). b Adjust with a screwdriver (small). ■ Correct thread tension The thread tension is correct when upper thread slightly appears on the wrong side of fabric. a b a Right side of fabric b Wrong side of fabric ■ Bobbin thread is too tight Upper thread on the right side of fabric seems to be lifting/looping and bobbin thread is not seen on the wrong side of fabric. a b a Right side of fabric b Wrong side of fabric If this occurs, turn the slotted-head screw (-) counterclockwise being careful not to over-loosen the screw, approximately 30-45 degrees to decrease bobbin tension. ■ Bobbin thread is too loose Bobbin thread appears slightly on the right side of fabric. a b a Right side of fabric b Wrong side of fabric If this occurs, turn the slotted-head screw (-) clockwise, being careful not to over-tighten the screw, approximately 30-45 degrees to increase bobbin tension. CAUTION ● When adjusting the bobbin case, be sure to remove the bobbin from the bobbin case. ● DO NOT adjust the position of the Phillips (+) screw on the bobbin case as this may result in damage to the bobbin case, rendering it unusable. ● If the slotted-head screw (-) is difficult to turn, do not use force. Turning the screw too much or providing force in either (rotational) direction may cause damage to the bobbin case. Should damage occur, the bobbin case may not maintain proper tension. 64