Brother International PR-600 Users Manual - English - Page 214

embroidering begins again.

|

View all Brother International PR-600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 214 highlights

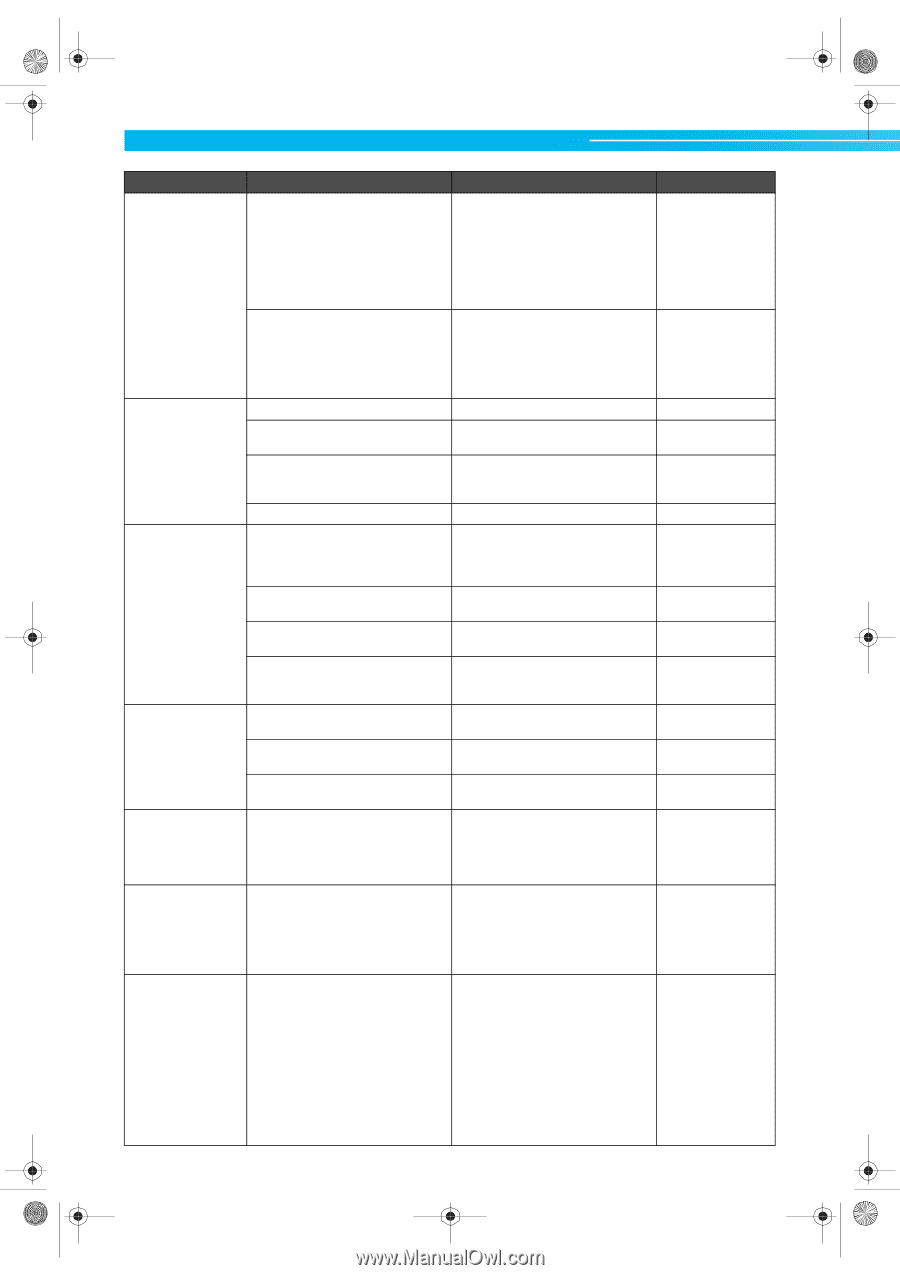

Sapphire.book Page 196 Friday, August 1, 2003 9:12 AM Appendix Symptom There are loops in the upper thread. The machine is noisy. The needle threader cannot be used. The thread tension is incorrect. The upper thread comes out of the needle when embroidering begins. The upper thread does not reach the bobbin thread when embroidering begins. Although the thread is not broken, a broken thread error occurs and the machine stops. 196 Probable Cause The thread tension does not correspond to the amount that the thread tension knob was tightened. The thread quality is poor. Lint may be wound in the hook. The upper thread is not threaded correctly. The hook is damaged. Not enough oil was applied. The needle is not at the correct position. Recommended needles are not used on this machine. The needle is not installed correctly. The hook on the automatic needle-threading mechanism is bent. The upper thread is not threaded correctly. The bobbin thread is not correctly threaded. The lower thread tension is incorrect. If a short length of thread remains after the thread is trimmed, the needle may become unthreaded when embroidering begins again. There is no more thread in the bobbin, the thread does not feed from the bobbin, or the thread that is fed from the bobbin is too short. If the thread breakage sensor in the thread tension disc of the thread tension knobs cannot detect that the thread is being fed, even if the machine is running, a broken thread error occurs and the machine is stopped. If the thread came out of the thread tension disc, even though the thread is not broken, the machine detects that the thread is not being fed and stops. Remedy If the thread tension cannot be adjusted, thread wax and dust may have collected in the subtension thread tension disc at the front and back of the thread tension knob, causing the thread tension disc to rise. Clean the thread tension disc. Try sewing with different thread. If the problem no longer occurs after the thread is changed, the thread quality is the problem. Replace the thread with one of good quality. Clean the hook. Check the thread path, and then thread the upper thread again. Replace the hook. Consult your nearest authorized dealer. Oil recommended parts. Touch the key to move the desired needle bar to be threaded into embroidering position. Replace and use recommended needle. Correctly install the needle. Consult your nearest authorized dealer. Check the thread path, and then thread the upper thread again. Correctly thread the bobbin thread. Adjust the tension of the bobbin thread. Set the remaining length of thread to "LONG TAIL" on the second page of the settings screen. Correctly thread the lower thread. Correctly pass the thread through the thread tension disc. If the broken thread error occurs after the machine is rethreaded, the sensor may be damaged. Consult your nearest authorized dealer. Reference Page p.183 p.35 p.186 p.40 p.15, 61 p.15, 61 p.15, 61 p.35 p.19 p.83 p.150 p.19 p.37