Brother International PR-600 Users Manual - English - Page 28

Preparing the thread guide, assembly

|

View all Brother International PR-600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 28 highlights

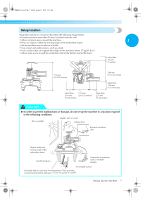

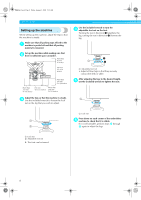

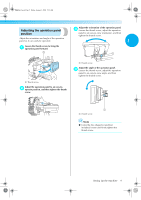

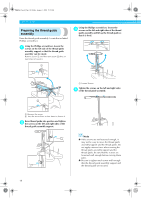

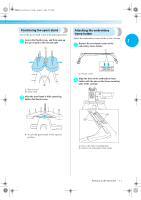

Sapphire.book Page 10 Friday, August 1, 2003 9:12 AM GETTING READY Preparing the thread guide assembly Raise the thread guide assembly. Locate the included Phillips screwdriver. Using the Phillips screwdriver, loosen the 1 screws on the left side of the thread guide assembly support so that the thread guide assembly can be raised. Remove screw 1, and then turn screw 2 three or four times to loosen it. Using the Phillips screwdriver, loosen the 3 screws on the left and right sides of the thread guide assembly and lift up the thread guide so that it is level. 1 1 Loosen Screws Tighten the screws on the left and right sides 4 of the thread guide assembly. 1 Remove the screw. 2 Turn the screw three or four times to loosen it. Raise thread guide into position and tighten 2 the screws on the left and right sides of the thread guide assembly support. Note ● If the screws are not loosened enough, it may not be easy to move the thread guide assembly support and the thread guide. Do not apply extreme force when moving the thread guide assembly support and the thread guide. Be sure that the screws are loosened well enough before moving these parts. ● Be sure to tighten each screw well enough that the thread guide assembly support and the thread guide are secured. 10