Craftsman 305cc Owners Manual - Page 10

Gasand Oil Fill-up

|

View all Craftsman 305cc manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

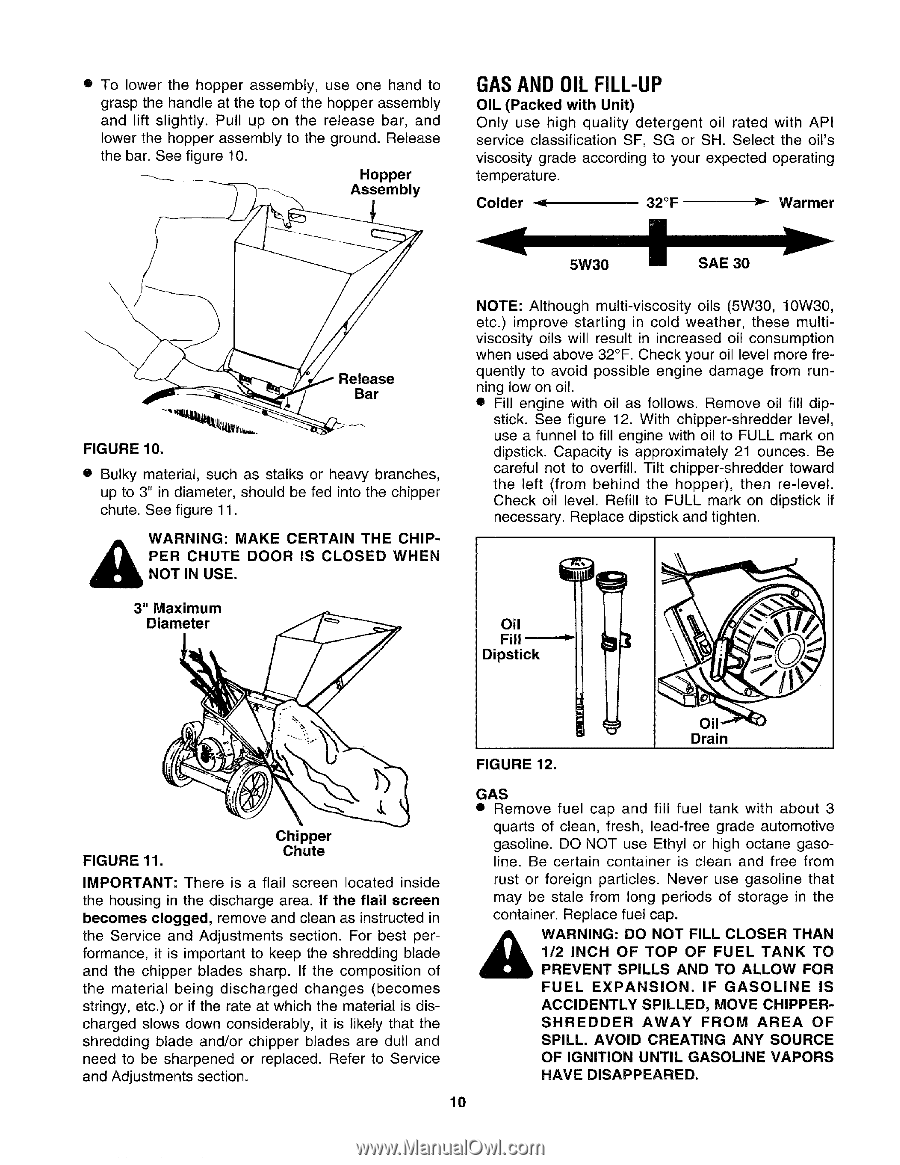

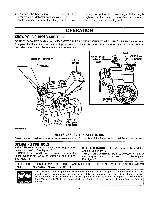

• To lower the hopper assembly, use one hand to grasp the handle at the top of the hopper assembly and lift slightly. Pull up on the release bar, and lower the hopper assembly to the ground. Release the bar. See figure 10. ---______ Hopper _ ---. Assembly FIGURE 10. • Bulky material, such as stalks or heavy branches, up to 3" in diameter, should be fed into the chipper chute. See figure 11. WARNING: MAKE CERTAIN THE CHIP- PNEORT ICNHUUSTEE. DOOR IS CLOSED WHEN 3" Maximum Diameter GASAND OIL FILL-UP OIL (Packed with Unit) Only use high quality detergent oil rated with API service classification SF, SG or SH. Select the oil's viscosity grade according to your expected operating temperature. Colder _ 32°F _- Warmer 5W30 SAE 30 NOTE: Although multi-viscosity oils (5W30, 10W30, etc.) improve starting in cold weather, these multiviscosity oils will result in increased oil consumption when used above 32°F. Check your oil level more frequently to avoid possible engine damage from running low on oil. • Fill engine with oil as follows. Remove oil fill dip- stick. See figure 12. With chipper-shredder level, use a funnel to fill engine with oi! to FULL mark on dipstick. Capacity is approximately 21 ounces. Be careful not to overfill. Tilt chipper-shredder toward the left (from behind the hopper), then re-level. Check oil level. Refill to FULL mark on dipstick if necessary. Replace dipstick and tighten. Oil Dipstick FIGURE 12. Oil Drain FIGURE 11. Chipper Chute IMPORTANT: There is a flail screen located inside the housing in the discharge area. If the flail screen becomes clogged, remove and clean as instructed in the Service and Adjustments section. For best performance, it is important to keep the shredding blade and the chipper blades sharp. If the composition of the material being discharged changes (becomes stringy, etc.) or if the rate at which the material is discharged slows down considerably, it is likely that the shredding blade and/or chipper blades are dull and need to be sharpened or replaced. Refer to Service and Adjustments section. GAS • Remove fuel cap and fill fuel tank with about 3 quarts of clean, fresh, lead-free grade automotive gasoline. DO NOT use Ethyl or high octane gasoline. Be certain container is clean and free from rust or foreign particles. Never use gasoline that may be stale from long periods of storage in the container. Replace fuel cap. 1/2 INCH OF TOP OF FUEL TANK TO WPRAERVNEINNGT: SDPOILLNSOTANFDILLTOCLAOLSLEORW THFAONR FUEL EXPANSION. IF GASOLINE IS ACCIDENTLY SPILLED, MOVE CHIPPERSHREDDER AWAY FROM AREA OF SPILL. AVOID CREATING ANY SOURCE OF IGNITION UNTIL GASOLINE VAPORS HAVE DISAPPEARED. 10