Dewalt DW08802CG Instruction Manual - Page 10

Using the Laser

|

View all Dewalt DW08802CG manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

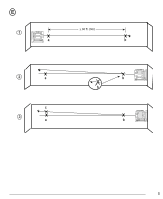

E 4. Move the laser to the opposite end of the wall (Figure E 6. Where the vertical laser beam appears on the ceiling, mark 2 ). b , directly beside the first mark a . 5. Position the laser toward the first end of the same wall and parallel to the adjacent wall. 6. Adjust the height of the laser so the center of the beam is 7. Measure the distance between a and b . 8. If your measurement is greater than the Allowable Distance Between a and b for the corresponding aligned with b . Ceiling Height D in the following table, the laser must be 7. Directly above or below a , mark c along the laser beam (Figure E 3 ). serviced at an authorized service center. Allowable Distance 8. Measure the distance between a and c . Ceiling Height D Between a and b 9. If your measurement is greater than the Allowable Distance Between a and c for the corresponding Distance Between a and b in the following table, the laser must be serviced at an authorized service center. 8′ (2.5m) 10′ (3.0m) 14′ (4.0m) 20′ (6.0m) 5/32" (3.5mm) 3/16" (4.5mm) 1/4" (6.0mm) 3/8" (9.0mm) Distance Between a and b 30′ (9m) 40′ (12m) 50′ (15m) Allowable Distance Between a and c 15/32" (12mm) 9/16" (14.4mm) 23/32" (18mm) 30′ (9.0m) 1/2" (13.0mm) Using the Laser Operating Tips Vertical Beam - Plumb • Always mark the center of the beam (dot) created by the laser. Checking the vertical (plumb) calibration of the laser can be • Extreme temperature changes may cause movement of most accurately done when there is a substantial amount of internal parts that can affect accuracy. Check your accuracy vertical height available, ideally 30′ (9m), with one person on often while working. the floor positioning the laser and another person near a ceiling to mark the position of the beam. It is important to conduct a calibration check using a distance no shorter than the distance • If the laser is ever dropped, check to make sure it is still calibrated. of the applications for which the tool will be used. • As long as the laser is properly calibrated, the laser is self- leveling. Each laser is calibrated at the factory to find level as 1. On the floor between two walls, mark a 5 ft. (1.5 m) line long as it is positioned on a flat surface within average ± 4° that is parallel to the adjacent wall (Figure F 1 ). of level. No manual adjustments are required. 2. Move the Power/Transport Lock switch to the right (Figure • Use the laser on a smooth, flat, level, surface. A 3 ) to turn the laser ON in self-leveling mode and display the horizontal and vertical beams. Turning the Laser Off 3. Place the laser at one end of the line on the floor, making Slide the Power/Transport Lock switch to the OFF position sure the vertical laser beam is aligned and centered on the (Figure A 2 ) when the laser is not in use. If the switch is not line. placed in the OFF position, the laser will not turn off. 4. Where the vertical laser beam appears on the ceiling, mark a . (This should be directly over the midpoint of the line on the floor.) 5. Move the laser to the other end of the line on the floor (Figure F 2 ). 10