E-Z-GO RXV - Gas Owner Manual - Page 35

Fig. 22, Torque Specifications and Bolt Grades

|

View all E-Z-GO RXV - Gas manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 35 highlights

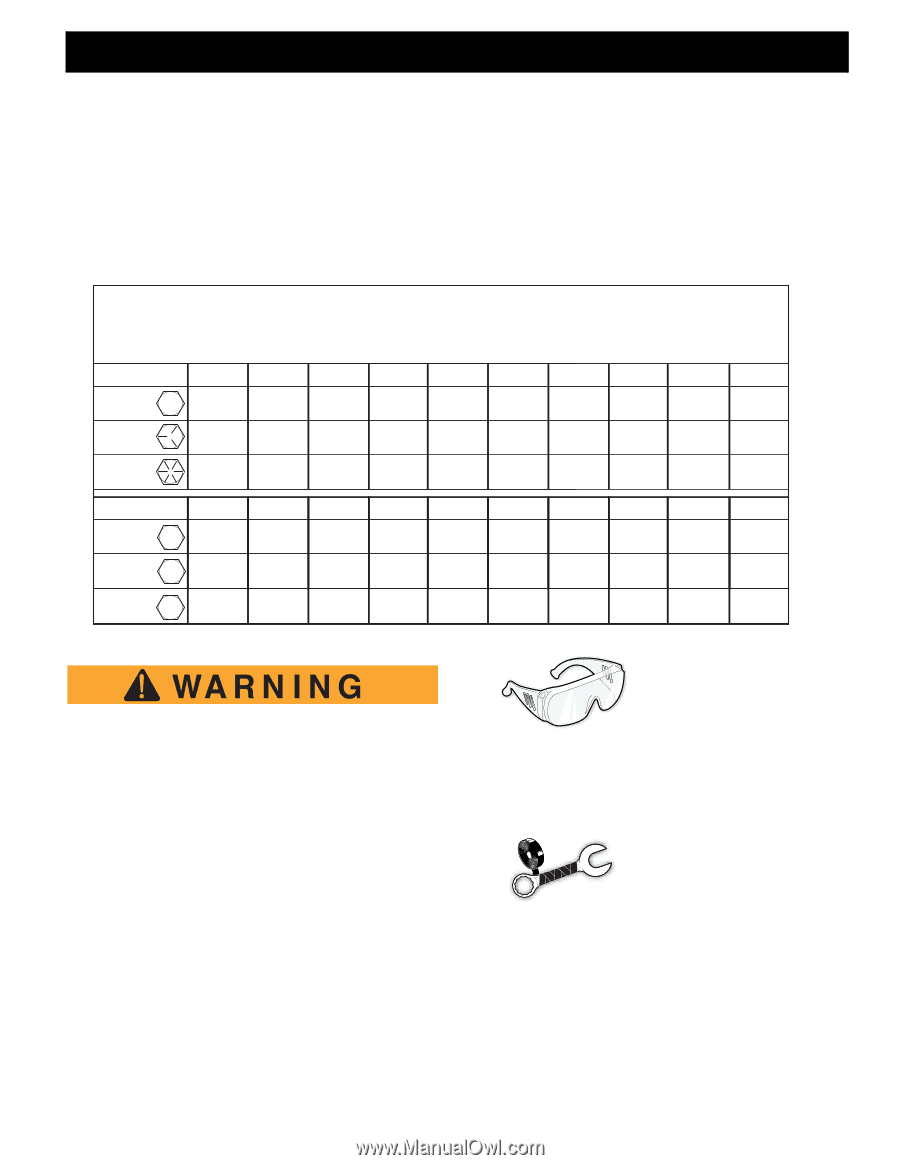

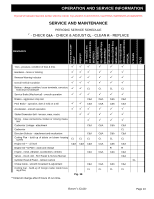

B OPERATION AND SERVICE INFORMATION Read all of manual to become familiar with this vehicle. Pay attention to all NOTICES, CAUTIONS, WARNINGS and DANGERS. HARDWARE Periodically, the vehicle should be inspected for loose fasteners. Fasteners should be tightened in accordance with the Torque Specifications table (Ref. Fig. 22). Use care when tightening fasteners and refer to the Technician's Repair and Service Manual for specific torque values. B Generally, three grades of hardware are used in the ve- hicle. Grade 5 hardware can be identified by the three marks on the hexagonal head and grade 8 hardware is identified by 6 marks on the head. Unmarked hardware is Grade 2 (Ref. Fig. 22). ALL TORQUE FIGURES ARE IN FT. LBS. (Nm) Unless otherwise noted in text, tighten all hardware in accordance with this chart. This chart specifies 'lubricated' torque figures. Fasteners that are plated or lubricated when installed are considered 'wet' and require approximately 80% of the torque required for 'dry' fasteners. BOLT SIZE 1/4" 5/16" 3/8" 7/16" 1/2" 9/16" 5/8" 3/4" 7/8" 1" Grade 2 4 8 15 24 35 55 75 130 125 190 (5) (11) (20) (33) (47) (75) (102) (176) (169) (258) Grade 5 6 13 23 35 55 80 110 200 320 480 (8) (18) (31) (47) (75) (108) (149) (271) (434) (651) Grade 8 6 18 35 55 80 110 170 280 460 680 (8) (24) (47) (75) (108) (149) (230) (380) (624) (922) BOLT SIZE M4 Class 5.8 1 (Grade 2) 5.8 (2) Class 8.8 2 (Grade 5) 8.8 (3) Class 10.9 3 (Grade 8) 10.9 (4) M5 M6 M8 M10 M12 M14 2 4 10 20 35 55 (3) (6) (14) (27) (47) (76.4) 4 7 18 35 61 97 (6) (10) (24) (47) (83) (131) 6 10 25 49 86 136 (8) (14) (34) (66) (117) (184) Fig. 22 Torque Specifications and Bolt Grades To reduce the possibility of severe injury or death from improper servicing techniques: DO NOT attempt any type of servicing operations before reading and understanding all notes, cautions and warnings in this manual. Any servicing requiring adjustments to be made to the powertrain while the motor is running must be made with both drive wheels raised and vehicle properly supported on jack stands. To reduce the possibility of motor damage, never operate vehicle at full throttle for more than 4 - 5 seconds while vehicle is in a 'no load' condition. Wear eye protection when working on the vehicle. Use extra care when working around batteries, or using solvents or compressed air. To reduce the possibility of causing an electrical arc, which could result in a battery explosion, turn off all electrical loads from the battery before removing battery wires. explosion. Wrap wrenches with vinyl tape to reduce the possibility of a dropped wrench 'shorting out' a battery, which could result in an Reduce the possibility of accidental starting by removing and grounding spark plug wires and disconnecting battery at negative terminal before servicing. The electrolyte in a battery is an acid solution which can cause severe burns to the Owner's Guide Page 15