Intermec PX6i Intermec Direct Protocol 8.60 Programmer's Reference Manual - Page 124

Instructions in Alphabetic Order

|

View all Intermec PX6i manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 124 highlights

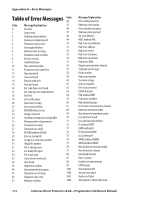

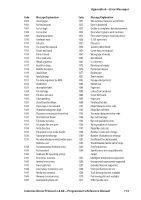

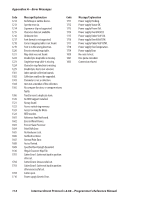

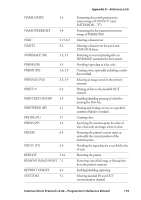

Appendix B-Reference Lists Instructions in Alphabetic Order Instruction Chapter Purpose ALIGN (AN) 3.2 Specifying which part (anchor point) of a text, bar code field, image field, line, or box will be positioned at the insertion point. BARFONT (BF) 3.4 Specifying fonts for the printing of bar code interpretation. BARFONT (BF) ON/OFF 3.4 Enabling/disabling the printing of bar code interpretation. BARHEIGHT (BH) 3.4 Specifying the height of a bar code. BARMAG (BM) 3.4 Specifying the magnification in regard of width of the bars in a bar code. BARRATIO (BR) 3.4 Specifying the ratio between the wide and the narrow bars in a bar code. BARSET 3.4, 8.1 Specifying a bar code and setting additional parameters to complex bar codes. BARTYPE (BT) 3.4 Specifying the type of bar code. BEEP 5.10 Ordering the printer to emit a beep. BREAK 5.18 Specifying a break interrupt character for the keyboard or a serial communication channel. BREAK ON/OFF 5.18 Enabling/disabling break interrupt separately for the keyboard and each serial communication channel. CLEANFEED 4.1 Running the printer's feed mechanism. CLIP 3.2 Enabling/disabling partial fields. CLL 4.3 Partial or complete clearing of the print image buffer. COPY 7.3 Copying files. COUNT& 5.6 Creating a counter. CUT 4.1 Activating an optional paper cutting device. CUT ON/OFF 5.8 Enabling/disabling automatic cutting after PRINTFEED execution and optionally adjusting the media feed before and after the cutting. 116 Intermec Direct Protocol v.8.60-Programmer's Reference Manual