JET Tools JWP-15HH User Manual - Page 12

Table Rollers, Cutterhead, Installing and replacing knives, straight cutterhead only

|

View all JET Tools JWP-15HH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

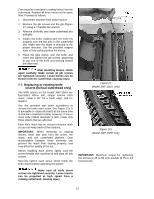

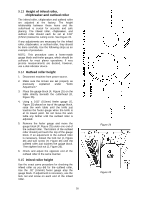

9.3 Table Rollers Your planer is supplied with two table rollers (Figure 14) which turn as the stock is fed into the machine, thus reducing friction. It is not possible to give exact dimensions on the proper height setting of the table rollers because each type of wood behaves differently. As a general rule, however, when planing rough stock the table rollers should be set at high position. When planing smooth stock the rollers should be set at low position. NOTE: When raising the roller higher above the table, the range is from zero to 0.06" (Figure 15). The table rollers are factory set for average planing and are parallel to the table surface. If you desire to adjust the table rollers higher or lower, proceed as follows: 1. Disconnect machine from power source. 2. Lay a straight edge across both rollers. 3. On one side of the table, loosen the set screws (A, Figure 14) with a 3mm hex wrench, and turn the eccentric shafts (B, Figure 14) to raise or lower the rollers. 4. When proper height is achieved, tighten set screws. 5. Adjust the rollers from the opposite side of the table in the same manner. IMPORTANT: Be sure that the height of front and rear rollers are the same. And the table rollers must always be set parallel to the table. 9.4 Cutterhead Although your planer was carefully adjusted at the factory, it should be checked before being put into operation. Any inaccuracies due to rough handling in transit can be corrected by following the directions in this manual. To check the adjustments you will need feeler gauges, and a home-made gauge block made of hardwood. This gauge block can be made by following the dimensions shown in Figure 16. 9.5 Installing and replacing knives (straight cutterhead only) Use caution and proceed slowly when working with and around the knives - they are extremely sharp. The planer knives are double-sided. If one side becomes dull, the knife can simply be rotated to use the new edge. When both edges have become worn, the knife must be replaced. 12 Figure 14 Figure 15 Figure 16