JET Tools JWP-15HH User Manual - Page 9

Grounding instructions

|

View all JET Tools JWP-15HH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

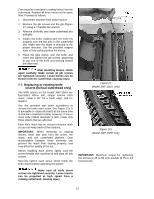

7.3 Extension tables The JWP-15DX extension tables have rollers; the JWP-15HH extension tables are cast iron. Both are installed in the same manner. 1. Mount an extension table to the edge of the main table with three M8 x 25 hex cap screws and washers (Figure 7) using a 12mm wrench. Do not fully tighten yet. 2. The extension table must be leveled with the main table. Place a straight edge (such as a carefully jointed board, or a steel bar) across the extension table and the main table. Move the straight edge to various points along the table during the procedure. NOTE: The straight edge should not lie over the raised table rollers, as this would distort the leveling process. Either place the straight edge just short of the table rollers, or lower the table rollers completely into the table (see page 12) until the extension tables have been installed. 3. Insert three socket set screws below the hex cap screws, using a 4mm hex wrench, and screw them in or out as needed until tables are level. 4. Securely tighten the hex cap screws. 5. Mount the second extension table to the opposite side of the planer table, using the same procedure. 7.4 Dust hood Mount the hood to the rear of the head casting with six M6 x 12 hex washer head screws (A, Figure 8). It is strongly recommended that you use a dust collection system with this planer. If you are not using a dust collection system, do not attach the dust hood to the planer, as the accumulation of dust inside the hood may create a safety hazard, or eventually cause jamming of the roller system in the cutterhead. 8.0 Grounding instructions Electrical connections must be made by a qualified electrician in compliance with all relevant codes. This machine must be properly grounded to help prevent electrical shock and possible fatal injury. In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. 9 Figure 7 Figure 8