JET Tools JWP-15HH User Manual - Page 19

Lubrication

|

View all JET Tools JWP-15HH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

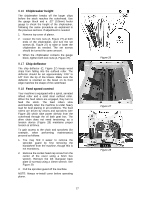

Remove resin and other accumulations from feed rollers and table with a soft rag and nonflammable solvent. Periodically check all the chains for proper tension and adjust accordingly if needed. The table should be kept clean and free of rust. Some users prefer a paste wax on exposed steel and cast iron surfaces. The wax provides a layer of protection as well as reducing friction between lumber and the table, making cuts faster and smoother. Avoid any wax that contains silicone or other synthetic ingredients. These materials can find their way into lumber and can make staining and finishing difficult. Another option is talcum powder applied with a blackboard eraser rubbed in vigorously once a week; this will fill casting pores and form a moisture barrier. This method provides a table top that is slick and allows rust rings to be easily wiped from the surface. Important also is the fact that talcum powder will not stain wood or mar finishes as wax pickup does. 10.1 Lubrication All ball bearings are factory lubricated and sealed for life. They require no further lubrication. The lubricant in the gear box must be drained and replaced every 2,500 hours. Multi-purpose gear box lubricant will be suitable. To replace the lubricant: 1. Remove the drain plug (A, Figure 32) with a 14mm wrench. Drain dirty oil thoroughly. 2. Insert and tighten the drain plug. (A, Figure 32). 3. Remove filler cap (B, Figure 32) and fill with clean lubricant through the hole. Fill until the oil reaches the top of the filler plug port for correct oil level. 4. Install and tighten filler cap (B, Figure 32). Figure 32 19