JET Tools JWP-15HH User Manual - Page 13

Replacing or rotating knife, inserts helical cutterhead only

|

View all JET Tools JWP-15HH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

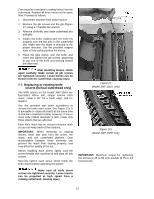

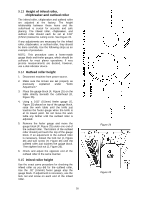

Care must be exercised in setting knives into the cutterhead. Replace all three knives at the same time. Proceed as follows: 1. Disconnect machine from power source. 2. Remove the gib screws and the gib (Figure 17) using a T-handle hex wrench. 3. Remove old knife, and clean cutterhead slot and gibs. 4. Install new knife, making sure the knife fits properly over the two pins in the cutterhead slot. Make sure the blade is oriented in the proper direction. Use the provided magnet tools to help safely position the knives. 5. Place the gibs evenly over the knife, and insert and tighten the gib screws, beginning at one end of the knife and working toward the other end. After installing knives, check again carefully. Make certain all gib screws are tightened securely. Loose knives can be thrown from the cutterhead, causing injury. 9.6 Replacing or rotating knife inserts (helical cutterhead only) The knife inserts on the model JWP-15HH are four-sided. When dull, simply remove each insert, rotate it 90° for a fresh edge, and reinstall it. Use the provided star point screwdriver to remove the knife insert screw. See Figure 17a. It is advisable to rotate all inserts at the same time to maintain consistent cutting. However, if one or more knife inserts develops a nick, rotate only those inserts that are affected. Each knife insert has an etched reference mark so you can keep track of the rotations. IMPORTANT: When removing or rotating inserts, clean saw dust from the screw, the insert, and the cutterhead platform. Dust accumulation between these elements can prevent the insert from seating properly, and may affect the quality of the cut. Before installing each screw, lightly coat the screw threads with machine oil and wipe off any excess. Securely tighten each screw which holds the knife inserts before operating the planer! Make sure all knife insert screws are tightened securely. Loose inserts can be propelled at high speed from a rotating cutterhead, causing injury. Figure 17 (Model JWP-15DX only) Figure 17a (Model JWP-15HH only) IMPORTANT: Maximum torque for tightening the screws is 45 to 55 inch pounds (3.75 to 4.6 foot pounds). 13