LiftMaster MEGA ARM / MEGA ARM TOWER MATDCBB Green Control Board V.6.4 or newe - Page 13

General Service, Shear Pin Replacement, Battery Disposal, Battery Replacement - federal

|

View all LiftMaster MEGA ARM / MEGA ARM TOWER manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

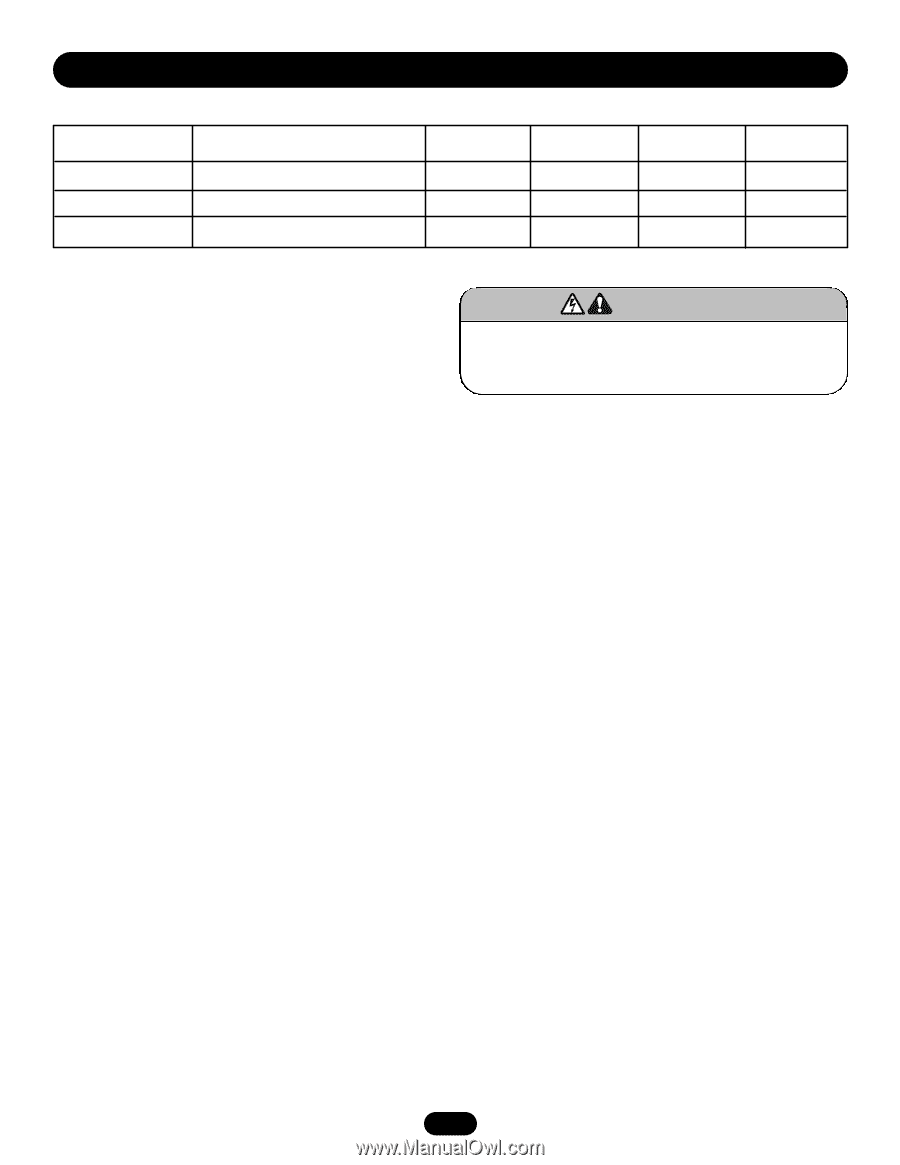

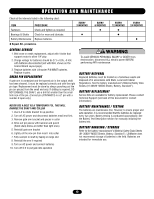

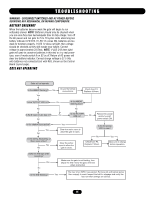

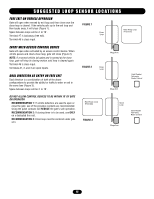

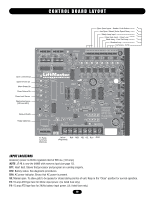

OPERATION AND MAINTENANCE Check at the intervals listed in the following chart: ITEM PROCEDURE Fasteners Check and tighten as required. Bearings & Shafts Check for wear and lubricate. Battery Maintenance Replace batteries. WARNING Repeat ALL procedures. EVERY 3 MONTHS EVERY 6 MONTHS EVERY 12 MONTHS ◆ ◆ ◆ WARNING EVERY 24 MONTHS CAUTION GENERAL SERVICE 1. Belt loose or needs replacement, adjust with 4 bolts that support motor to allow 1/4" play. 2. Charge voltage for batteries should be 27.5 +0.05, -0 Vdc with batteries disconnected (set with R63, shown on the Control Board Layout page). 3. Replace batteries with Liftmaster P/N MBAT batteries. Replace in pairs. SHEAR PIN REPLACEMENT If gate arm is vandalized and the tapered pin in the output shaft has been sheared, it must be replaced correctly and with the right pin type. Replacement must be done by always punching out the pin (or pieces) from the small end only. If drilling is required, DO AVERTISSEMENT NOT DAMAGE THE SHAFT, use a drill bit smaller than the small hole size of the pin. (Correct pin (P/N MA013) is a 2" pin with a number 6 taper only.) ATTENTION NEVER USE A BOLT AS A TEMPORARY FIX, THIS WILL DAMAGE THE SHAFT AND COLLAR 1. Use S-3 to rotate bracket to up position 2. Turn off AC power and disconnect batteries small end first. 3. Remove gate arm bracket and pieces in collar 4. Drive out pin pieces with hammer and punch (Solid sharp blows are better than light ones) 5. Reinstall gate arm bracket 6. Lightly oil the new pin then insert into collar 7. Fully seat pin in shaft by taping on large end 8. Reinstall the arm if required 9. Turn on AC power and connect batteries 10. Turn off S-3 to put gate into operation WARNING To avoid SERIOUS PERSONAL INJURY or DEATH from electrocution, disconnect ALL electric power BEFORE performing ANY maintenance. BATTERY DISPOSAL Replaced batteries must be treated as a hazardous waste and disposed of in accordance with State, Local and Federal Regulations. See the battery manufacturer's Material Safety Data Sheets (01-30839 "MSDS Sheets, Battery, Standard"). BATTERY REPALACVEEMERNTTISSEMENT Service Kits are available for battery replacement. Please contact Technical Support (see back of this document for contact information). AVERTISSEMENT BATTERY MAINTENANCE / TESTING The batteries are maintenance free. However, to insure proper and safe operation, it is recommended that the batteries be replaced every two years. Battery testing is conducted automatically. See the Battery Test Description section for manually initiating the battery test. BATTERY HANDLING / STORAGE Refer to the battery manufacturer's Material Safety Data Sheets (01-30839 "MSDS Sheets, Battery, Standard"). LiftMaster does not recommend storage of batteries in the field. Batteries are intended for immediate use. ADVERTENCIA ADVERTENCIA PRECAUCIÓN ADVERTENCIA 13