Panasonic EYFMA2C Owner s Manual - Page 17

Caution

|

View all Panasonic EYFMA2C manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

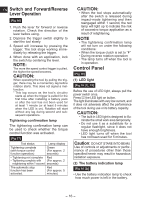

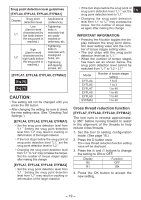

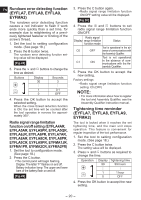

• Battery life varies slightly with ambient temperature and battery characteristics. The lamp is designed to provide a rough indication of remaining battery life. Indicator Battery status Fully charged Approx. 40% or less remaining Flashing Flashing Flashing Approx. 20% or less remaining (indicates need to recharge battery) The battery pack will need to be charged soon. No charge The battery pack needs to be charged. (The tool's automatic power-off function will activate at this stage.) Automatic power-off function • The automatic power-off function is designed to prevent a loss of tightening torque due to reduced battery voltage. Once it has been activated, the tool will not operate until the battery pack has been charged (or replaced with a fresh unit), even if the trigger is depressed. Indicator Flashing NOTE: • All 3 bars on the battery indication lamp will flash when the automatic power-off function is activated. • When the battery indication lamp begins flashing, the battery pack should be charged (or replaced with a fresh unit) immediately. • Be sure to fully charge the battery pack in question after activation of the automatic power-off function. Failure to do so may prevent the automatic power-off function from being properly deactivated. (3) The torque control function • The torque control function calculates EN the load from the motor's rotational angle during the hammer impact and determines that the bolt has been prop- erly seated when a preset load value is exceeded. Driving is then automati- cally stopped after a preset number of impacts have been delivered to the bolt. CAUTION: • Always check the tool's tightening torque before use. Improper tool operation may result in excessive or inadequate tightening. • Always operate the tool with the switch fully engaged. The torque control function will not operate when the switch is not sufficiently engaged, preventing the tool from stopping automatically. • In work where a heavy load comes to bear during tightening, the load may be interpreted as the seating of the bolt, preventing the bolt from being completely tightened. • Repeated tightening of the same bolt may break the bolt or deform the material into which the bolt is being driven as a result of excessive tightening. • The tightening torque value and precision vary with factors such as the material into which the bolt is being driven and the condition of the socket being used. Adjust the torque as necessary for the work being performed. Bolt tightening torque varies due to the factors described below. 1) Bolt • Bolt diameter: Tightening torque gener- ally increases with bolt diameter. • Torque coefficient (indicated by the bolt manufacturer), grade, length, etc. 2) Other • Bit and socket condition: Material, amount of play, etc. • Use of a universal joint or socket adapter • User: Manner in which the tool is applied to the bolt, strength with which the tool is held, manner in which the tool's switch is engaged • Condition of object being tightened: Material, seating surface finish - 17 -