Stihl FS 88 Instruction Manual - Page 39

FS 108

|

View all Stihl FS 88 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 39 highlights

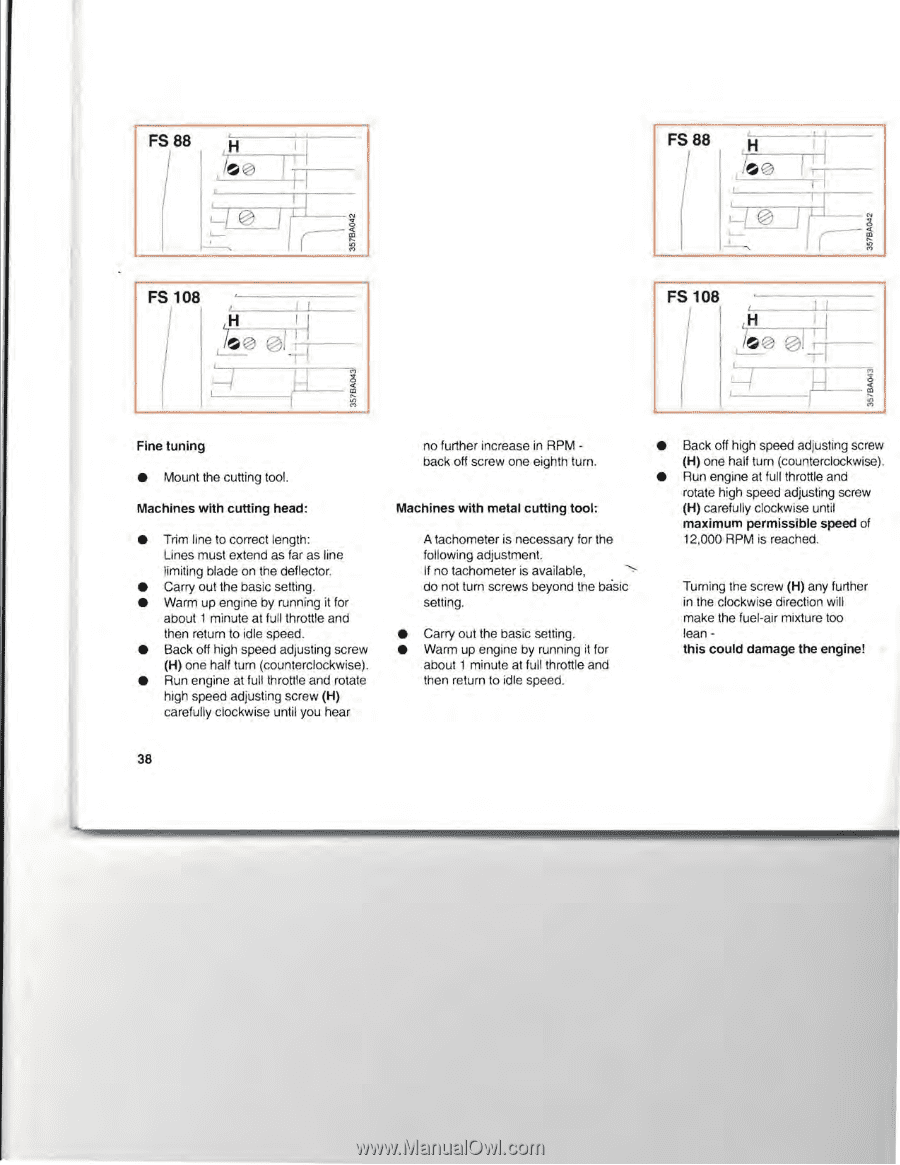

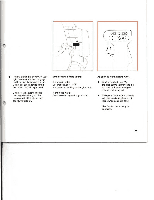

FS 88 I ~H ,~ ~I I-- --I----- FS 108 ( ,, IRii IILIL I, FS88 I , IH~@ !, Inr I --- 1Pr= 1'-1 @ lI FS 108 ( I, Fine tuning • Mount the cutting tool. Machines with cutting head: • Trim line to correct length: Lines must extend as far as line limiting blade on the deflector • Carry out the basic setting. • Warm up engine by running it for about 1 minute at full throttle and then return to idle speed. • Back off high speed adjusting screw (H) one half turn (counterclockwise). • Run engine at full throttle and rotate high speed adjusting screw (H) carefully clockwise until you hear no further increase in RPM - • back off screw one eighth turn. • Machines with metal cutting tool: A tachometer is necessary for the following adjustment. If no tachometer is available, .....,. do not turn screws beyond the basic setting. • Carry out the basic setting. • Warm up engine by running it for about 1 minute at full throttle and then return to idle speed. Back off high speed adjusting screw (H) one half turn (counterclockwise). Run engine at full throttle and rotate high speed adjusting screw (H) carefully clockwise until maximum permissible speed of 12,000 RPM is reached. Turning the screw (H) any further in the clockwise direction will make the fuel-air mixture too lean this could damage the engine! 38