Brother International BM-917B Instruction Manual - English - Page 21

Thread Tension, Caution

|

View all Brother International BM-917B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

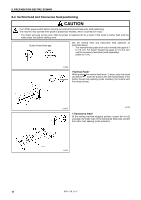

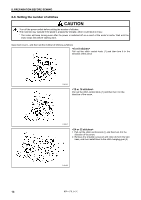

10. THREAD TENSION 10.THREAD TENSION CAUTION Turn off the power switch before carrying out this operation. The machine may operate if the pedal is pressed by mistake, which could result in injury. * The motor will keep turning even after the power is switched off as a result of the motor's inertia. Wait until the motor stops fully before starting work. When turning the machine pulley by hand, turn the pulley until the needle is at the final position after one cycle. If the needle is at a point midway through the cycle when the power is turned on, the machine will immediately start operating, which could result in injury. 10-1. Main thread tension Becomes weaker Becomes stronger The main thread tension is adjusted by turning the tension nut (1). 1995M 10-2. Adjusting the sub tension timing 1996M 45mm 10mm Reference line Quick looseing Slow looseing Sub tension ! Pass the thread through only the sub tension, and then while gently pulling the thread, check the timing at which the pressure of the tension discs (1) starts to loosen. ! Turn the machine pulley by hand to raise the needle bar (2) until the reference line is aligned with the top edge of needle bar bush U (3) (needle bar height 45 mm), and adjust the timing so that the tension discs (1) start to loosen at this point. 1. Loosen the set screw (4), and then turn the sub tension stud (5) to adjust the timing. 2. Tighten the set screw (4). Loosen 1997M 10-3. Adjusting the thread presser tension opening amount Opening amount becomes larger Loosen Opening amount becomes smaller Adjust so that the tension disc presser (1) opens by 0.5-0.8 mm when the sewing machine starts (when the machine pulley is turned by hand). 1. Loosen the nut (2), and then turn the thread presser tension stud (3) to adjust the opening amount. 2. Tighten the nut (2). 0.5-0.8mm 15 1998M BM-917B, 917C