Brother International BM-917B Instruction Manual - English - Page 32

Troubleshooting

|

View all Brother International BM-917B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 32 highlights

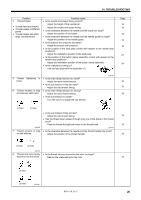

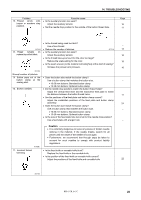

14. TROUBLESHOOTING Problem 4. Thread breaks • Thread frays and breaks. • Thread breaks at different points. • Thread breaks and stitch skips simultaneously Possible cause • Is the needle and looper timing correct? Adjust the height of the needle bar. Adjust the needle and looper timing. • Is the clearance between the needle and the looper too large? Adjust the position of the looper. • Is the clearance between the needle and the needle guide too large? Adjust the position of the needle guide. • Is the presser arm pressure too weak? Adjust the presser arm pressure. • Is the position of the feed plate correct with respect to the needle drop positions? Adjust the installation position of the feed plate. • Is the position of the button clamp assembly correct with respect to the needle drop positions? Adjust the installation position of the button clamp assembly. • Is the material bunching up? Use the feed plate with the projection (1). 5. Thread tightening is loose. 6. Thread remains in loop at crossover stitch joint • Is the main thread tension too weak? Adjust the main thread tension. • Is the sub tension timing too early? Adjust the sub tension timing. • Is the main thread tension too strong? Adjust the main thread tension. • Is the sub tension too weak? Turn the nut (1) to adjust the sub tension. 2061M (4 hole) (2 hole) 2062M 7. Thread remains in loop on odd stitches • Is the sub tension timing too late? Adjust the sub tension timing. • Has the thread been passed through only one of the holes in the thread hook? Pass the thread through both holes in the thread hook.. 2063M • Is the clearance between the needle and the thread handler too small? Adjust the position of the thread handler. Page ・ 18 18 ・ 19 ・ 19 ・ 16 ・ 24 ・ 24 ・ - ・ 15 ・ 15 ・ 15 15 ・ 10 ・ 19 (4-hole) (2-hole) 2062M 8. Thread end not properly • Is the thread take-up amount for the rotor too large? ・ wound on the first stitch. Reduce the scale setting for the rotor. 16 (4-hole) (2-hole) 2064M BM-917B, 917C 26