Brother International BM-917B Instruction Manual - English - Page 33

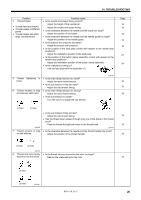

Adjust the installation positions of the feed plate and button clamp assembly.

|

View all Brother International BM-917B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 33 highlights

14. TROUBLESHOOTING Problem 9. Stitch joint is loose. (4-hole) (2-hole) Possible cause • Is the thread take-up amount for the thread take-up lever too small? Adjust the position of the thread take-up lever in accordance with the thread being used. • Is the thread presser tension too weak? Turn the nut (1) to adjust the thread presser tension. 2065M 10. Intermittent problems with thread tightening • Is the thread getting caught somewhere along the thread path? Check the threading of the thread. 2066M Page ・ 10 ・ - ・ 8 (4-hole) (2-hole) 2067M 11. Stitches skip at sewing • Is the main thread tension too strong? ・ start Adjust the main thread tension so that 64-70 mm of thread trails out ・ Not enough stitches from the hole in the needle. 2069M 15 ・ • Is the needle properly installed? ・ If it is incorrect, install the needle correctly. 64-70mm 8 • Is the thread presser tension opening amount too small? ・ (4-hole) Adjust the thread presser tension opening amount. 15 Not enough stitches • Is the thread take-up amount for the rotor too small? Increase the scale setting for the rotor. ・ 16 • Are the positions of the feed plate and button clamp correct? ・ Adjust the installation positions of the feed plate and button clamp assembly. 24 (2-hole) • Is the needle and looper timing correct? ・ Adjust the height of the needle bar. 18 Adjust the needle and looper timing. 18 • Is the clearance between the needle and the looper too large? ・ Adjust the position of the looper. 19 • Is the clearance between the needle and the needle guide too large? ・ Adjust the position of the needle guide. 19 • Is the material bunching up? ・ Use the feed plate with the projection (1). - 2068M 2061M 12. Final stitch skips • Is the needle properly installed? ・ Stitch comes out when If it is incorrect, install the needle correctly. 8 the material is removed • Are the positions of the feed plate and button clamp correct? ・ from the machine. Adjust the installation positions of the feed plate and button clamp assembly. 24 • Is the needle and looper timing correct? ・ Adjust the height of the needle bar. 18 Adjust the needle and looper timing. 18 • Is the clearance between the needle and the looper too large? ・ Adjust the position of the looper. 19 • Is the clearance between the needle and the needle guide too large? ・ Adjust the position of the needle guide. 19 27 BM-917B, 917C