Brother International BM-917B Instruction Manual - English - Page 25

Adjusting the needle and looper clearance, 4. Adjusting the needle guide, 5. Adjusting the thread

|

View all Brother International BM-917B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

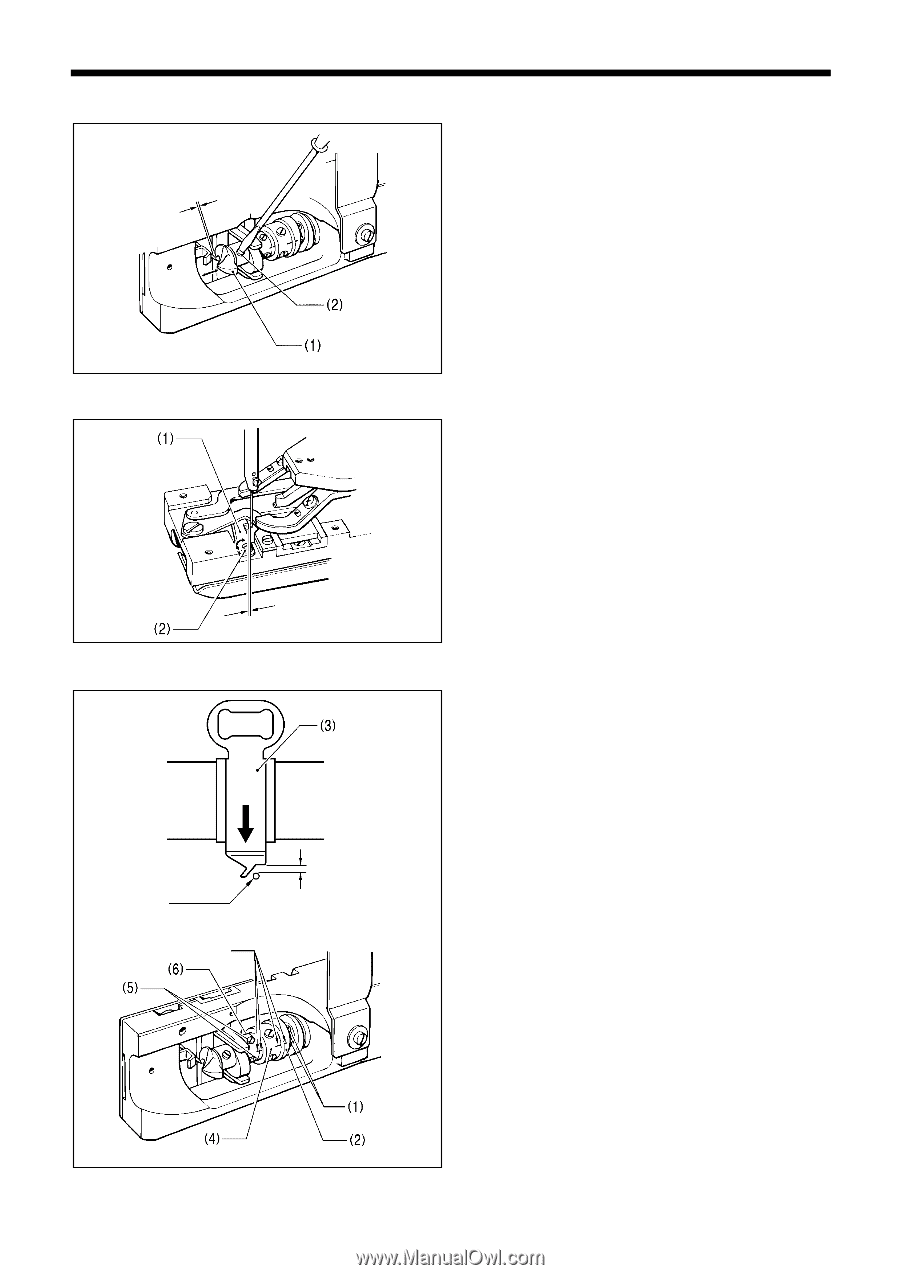

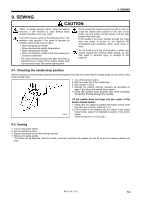

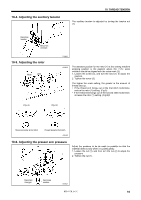

12. STANDARD ADJUSTMENTS 12-3. Adjusting the needle and looper clearance 0.03-0.08mm Adjust so that the clearance between the needle and the tip of the looper (1) is 0.03-0.08 mm when the needle bar rises from its lowest position until the tip of the looper (1) is aligned with the center of the needle. 1. Loosen the set screw (2), and then move the looper (1) to adjust the clearance. 2. Tighten the set screw (2). 12-4. Adjusting the needle guide 2007M Adjust the clearance between the needle and the needle guard (1) to 0.1-0.2 mm. 1. Remove the feed plate and the needle plate. 2. Loosen the screw (2), and then move the needle guard (1) to adjust the clearance. 3. Tighten the screw (2). 4. Install the feed plate and the needle plate. 0.1-0.2mm 12-5. Adjusting the thread handler Needle Reference Lines 0.5-0.7mm 2008M 2009M 1. Turn the machine pulley to set the needle bar to its lowest position. 2. Loosen the two set screws (1). 3. Turn the grooved cam (2) to move the thread handler (3) to the maximum forward position. 4. Move the grooved cam (2) forward or back to adjust so that the clearance between the needle and the thread handler (3) is 0.5-0.7 mm at this time. 5. Turn the grooved cam (2) to align the reference line with the reference line of the looper setting shaft (4). 6. Tighten the set screws (1). 1. Loosen the two set screws (5). 2. Turn the triangular cam (6) to align the reference line with the reference line of the looper setting shaft (4). 3. Tighten the set screws (5). 2010M 19 BM-917B, 917C