Brother International LK3-B434E MKII Instruction Manual - English - Page 6

Contents, Setting The Work Clamp Mode

|

View all Brother International LK3-B434E MKII manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

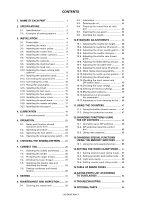

CONTENTS 1. NAME OF EACH PART 01 2. SPECIFICATIONS 02 2-1. Specifications 2 2-2. Examples of sewing patterns 3 3. INSTALLATION 04 3-1. Power table 4 3-2. Installing the motor 5 3-3. Installing the motor pulley 5 3-4. Installing the control box 6 3-5. Installing the rubber cushions 7 3-6. Installing the oil pan 7 3-7. Installing the cushions 7 3-8. Installing the machine head 8 3-9. Installing the head rest 8 3-10. Installing the liquid cooling tank, optional 8 3-11. Installing the operation panel 9 3-12. Connecting the ground wire 9 3-13. Connecting the cords 10 3-14. Piping (for pneumatic 12 3-15. Installing the V-belt 14 3-16. Installing the belt cover 15 3-17. Installing the foot switch 15 3-18. Installing the motor cover 16 3-19. Installing the spool stand 16 3-20. Installing the needle sub plate 17 3-21. Installing the eye guard 18 4. LUBRICATION 19 4-1. Lubrication points 19 5. OPERATION 20 5-1. Name and function of each operation panel item 20 5-2. Operating procedure 22 5-3. Operating the foot switch 23 5-4. Operating the emergency stop switch ... 24 6. CHECKING THE SEWING PATTERN ....... 25 7. CORRECT USE 26 7-1. Selecting the needle and thread ........ 26 7-2. Installing the needle 26 7-3. Threading the upper thread 26 7-4. Winding the lower thread 27 7-5. Replacing the bobbin case and threading the thread 28 7-6. Sewing conditions and thread tension 28 8. SEWING 31 9. MAINTENANCE AND INSPECTION ....... 32 9-1. Cleaning the rotary hook 32 9-2. Lubrication 33 9-3. Draining the oil 34 9-4. Cleaning the control box air inlet port 34 9-5. Cleaning the eye guard 34 9-6. Checking the needle 34 10.STANDARD ADJUSTMENTS 35 10-1. Adjusting the needle bar height ......... 35 10-2. Adjusting the needle bar lift amount ..... 35 10-3. Adjusting the driver needle guard ..... 36 10-4. Adjusting the needle clearance .......... 36 10-5. Adjusting the shuttle race thread guide 36 10-6. Adjusting the thread take-up amount .... 37 10-7. Adjusting the movable knife 37 10-8. Adjusting the work clamp lift amount ... 40 10-9. Work clamp interchangeability 41 10-10.Adjusting the needle up stop position ... 41 10-11.Adjusting the thread wiper 42 10-12.Checking the input sensor and DIP switch input 43 10-13.Checking the input voltage 44 10-14.Clearing all memory settings 44 10-15.Moving stitch patterns 45 10-16.Adjustment of air pressure (for pneumatic 46 10-17.Adjustment of inner clamping device .... 46 11.USING THE COUNTERS 47 11-1. Using the bobbin thread counter ....... 47 11-2. Using the production counter 47 12.CHANGING FUNCTIONS USING THE DIP SWITCHES 48 12-1. Operation panel DIP switches 48 12-2. DIP switches inside the control box 49 12-3. Using user programs 50 13.CHANGING SPECIAL FUNCTIONS USING THE MEMORY SWITCHES ........ 52 13-1. Using the cycle sewing function ........ 55 14.SETTING THE WORK CLAMP MODE .... 57 14-1. Setting solenoid work clamp mode ... 57 14-2. Setting pneumatic work clamp mode .... 57 14-3. Light work clamp 58 14-4. Setting reverse work clamp mode ..... 59 15.TABLE OF ERROR CODES 60 16.GAUGE PARTS LIST ACCORDING TO SUBCLASSES 62 17.TROUBLESHOOTING 65 18.OPTIONAL PARTS 68 LK3-B434E Mark II