Konica Minolta magicolor 1600W Service Manual - Page 90

Print control temperatures

|

View all Konica Minolta magicolor 1600W manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 90 highlights

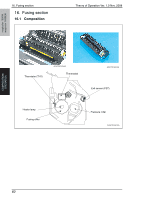

magicolor 1600W magicolor 1650EN COMPOSITION/ OPERATION Theory of Operation Ver. 1.0 Nov. 2008 16. Fusing section 16.3.3 Print control • To ensure a good fixing level and light transmission performance of the OHP transparencies, the fusing speed and fusing roller temperature are controlled. A. Control start timing • A print request is received. B. Control termination timing • A malfunction or media misfeed occurs. C. Print control temperatures • The fusing roller temperature is set according to the type of media, main body interior temperature (as measured by the temperature/humidity sensor), and warm-up start decision. • For types of media other than plain paper, the fusing speed is controlled at the 1/2 speed. D. Print control temperature adjustments • The temperature during print control is adjusted using the menu available from the control panel. The temperature can, however, be decreased only. • Adjustment steps are 0°C, -5°C, and -10°C. 16.3.4 Protection against abnormally high temperature • The machine provides protection at three different stages to prevent abnormally high temperature of the Fusing unit. A. Soft protection • If the Thermistor (TH1) detects a temperature exceeding a predetermined value, the mal- function code representing abnormally high temperature is displayed. At this time, the power supply line is shut down. • If the temperature of the fusing roller does not reach a predetermined value within a predetermined period of time after the start of the warm-up cycle, the power supply line is shut down. B. Hard protection • If the CPU overruns and the output level of the CPU of the Mechanical control board becomes a HIGH or LOW level, and not a pulse output, and a predetermined temperature or higher is detected, a circuit within the Mechanical control board turns OFF the relay to shut down each power supply line. C. Thermostat protection • If detection of abnormally high temperatures by soft protect or hard protect cannot be made due to a faulty Thermistor (TH), the thermostat operates at a predetermined temperature to shut down the power supply line. • If detection of abnormally high temperatures by soft protect or hard protect cannot be made due to a faulty Thermistor (TH), the thermostat operates at a predetermined temperature to shut down the power supply line. 63