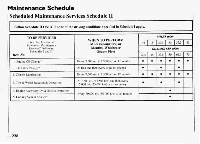

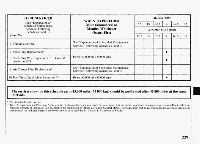

1994 Pontiac Grand Am Owner's Manual - Page 231

1994 Pontiac Grand Am Manual

Page 231 highlights

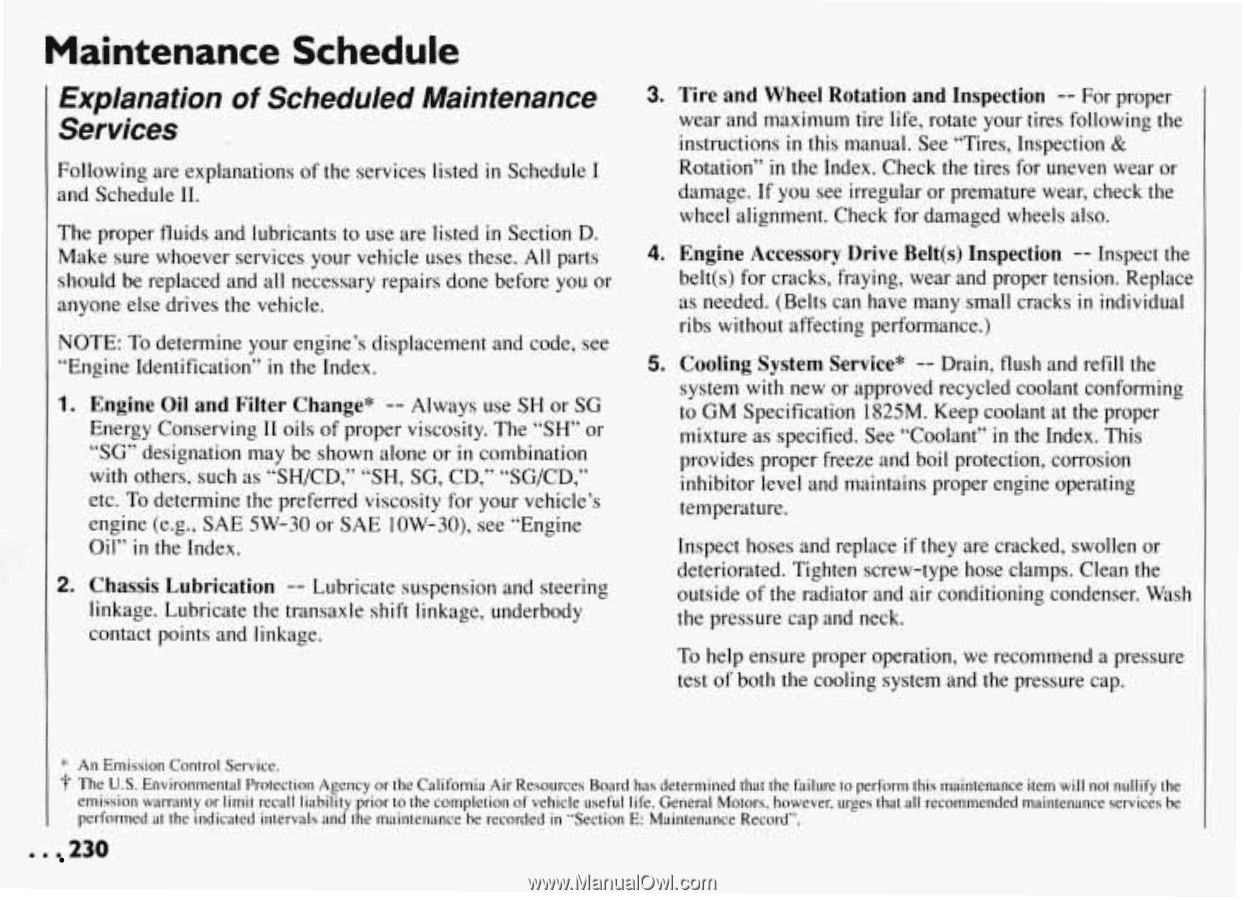

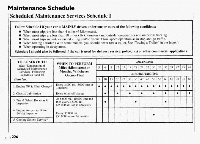

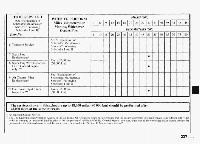

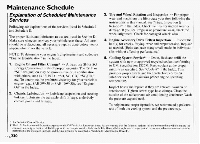

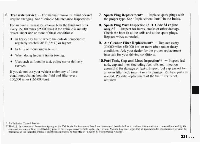

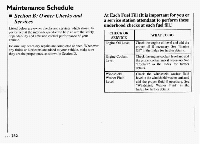

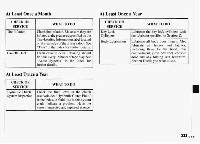

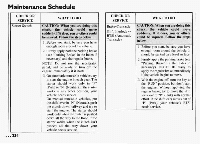

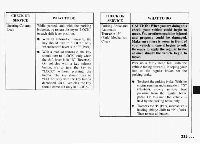

Maintenance Schedule Explanation of Scheduled Maintenance Services Following are explanations of the services listed in Schedule I and Schedule 11. The proper fluids and lubricants to use are listed in Section D. Make sure whoever services your vehicle uses these. All parts should be replaced and all necessary repairs done before you or anyone else drives the vehicle. NOTE: To determine your engine's displacement and code, see "Engine Identification" in the Index. 1. Engine Oil and Filter Change* -- Always use SH or SG Energy Conserving I1 oils of proper viscosity. The "SH" or "SG" designation may be shown alone or in combination with others, such as "SH/CD," "SH, SG, CD," "SG/CD," etc. To determine the preferred viscosity for your vehicle's engine (e.g., SAE 5W-30 or SAE 10W-30), see "Engine Oil" in the Index. 3. Tire and Wheel Rotation and Inspection -- For proper wear and maximum tire life, rotate your tires following the instructions in this manual. See "Tires, Inspection & Rotation" in the Index. Check thetires for uneven wear or damage. If you see irregular or premature wear, check the wheel alignment, Check for damaged wheels also. 4. Engine Accessory Drive Belt(s) Inspection -- Inspect the belt(s) for cracks, fraying, wear and proper tension. Replace as needed. (Belts can have many small cracks in individual ribs without affecting performance.) 5. Cooling System Service* -- Drain, flush and refill the system with new or approved recycled coolant conforming to GM Specification 1825M. Keep coolant at the proper mixture as specified. See "Coolant" in the Index. This provides proper freeze and boil protection, corrosion inhibitor level and maintains properengine operating temperature. Inspect hoses and replace if they are cracked, swollen or deteriorated. Tighten screw-type hose clamps. Clean the outside of the radiator andair conditioning condenser.Wash the pressure cap and neck. To help ensure proper operation, we recommend a pressure test of both the cooling system and the pressure cap. 2. Chassis Lubrication -- Lubricate suspension and steering linkage. Lubricate the transaxle shift linkage, underbody contact points and linkage. .. 230