Bernina 2500DCET Manual - Page 51

Cover stitch sewing test and, fine tuning, Fine tuning top & bottom cover, stitch, Fine tuning

|

View all Bernina 2500DCET manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 51 highlights

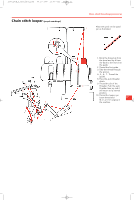

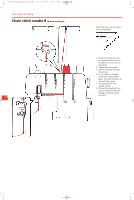

2500_DCE_2_englisch_neu 09.10.2007 15:00 Uhr Seite 51 A B CE D E AB C D Cover stitch sewing test and fine tuning Cover stitch sewing test and fine tuning After threading, check that the stitch selection dial is on your desired position for F. Test sew. Starting to sew: Raise the presser foot and place a double layer of fabric under the presser foot and needles. Lower the presser foot. To make the first stitch, turn the handwheel towards you to check the position of the needles. Sew. When sewing is interrupted, the needles stop in the fabric. When sewing is complete, raise the needles by turning the handwheel away from you (clockwise). This releases the needle threads from the lower looper. Do not use the needle stop button! Raise the presser foot and remove work towards the left. Cut threads (thread cutter). Fine tuning top & bottom cover stitch Compare your result with the stitch formation on the threading diagram in the looper cover. 51 The needle threads form two or three straight lines on the upperside of the fabric. They appear as dots on the underside of the fabric. The wiper thread forms horizontal loops between the two or three needle threads on the upper side of the fabric. The looper thread forms horizontal and vertical loops between the two or three rows of needle threads on the underside of the fabric to give a stretchy, durable seam. Incorrect stitch formation can be corrected by fine tuning. To increase the tension push the fine tuning lever up. To reduce the tension push the fine tuning lever down. A Fine tuning for the needle L thread (yellow) B Fine tuning for the needle C thread (green) C Fine tuning for the needle R thread (brown) D Fine tuning for the lower looper (purple) E Fine tuning for the wiper thread (grey) Fine tuning If the needle threads form loops on the underside of the fabric: Increase the needle thread tensions. Tip: When using decorative threads, attach the deco guide (see page 36) over the looper threading path. Do not thread the first machine guide but take the thread directly through the deco guide. Note: If using needle system JLx2, reduce the needle thread tensions slightly.