Craftsman 28933 Operation Manual - Page 119

Adjustments

|

View all Craftsman 28933 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 119 highlights

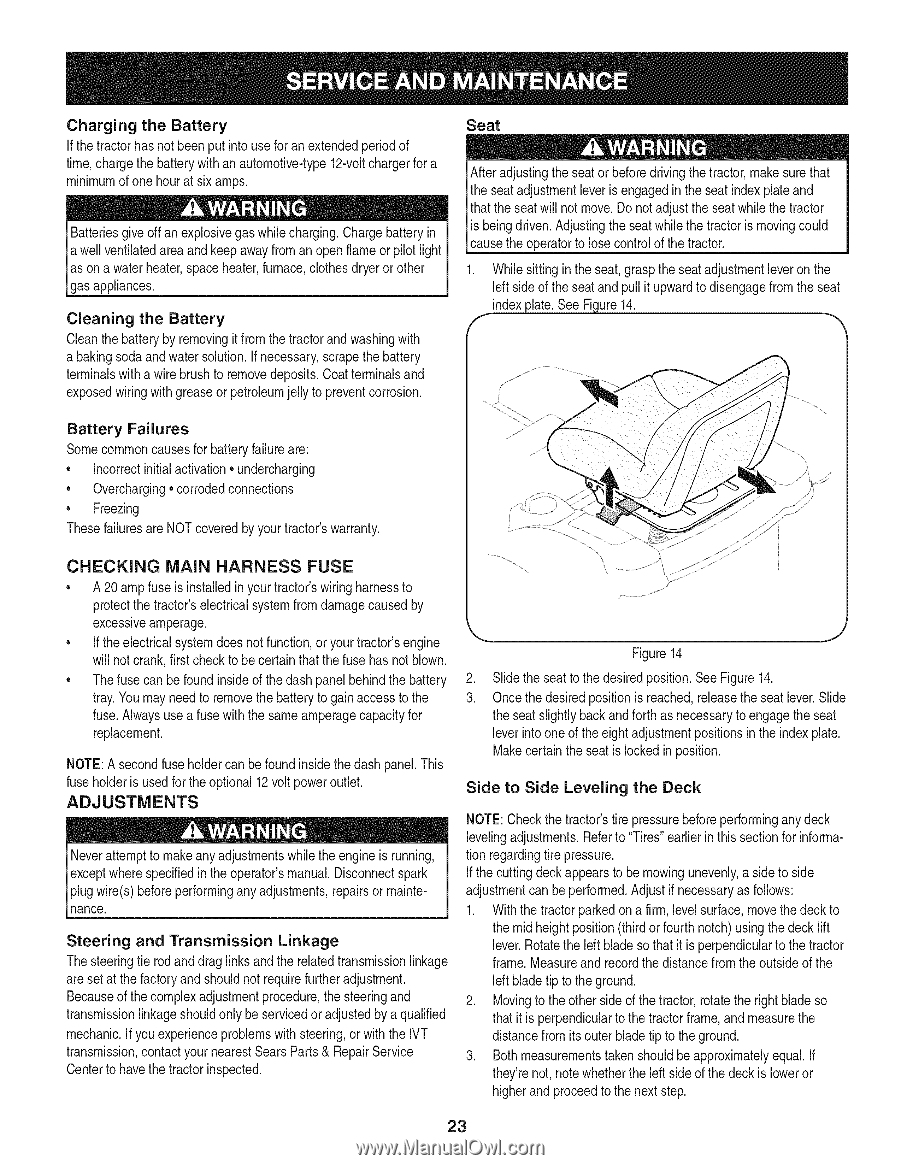

Charging the Battery If thetractorhas notbeen put intouse for an extendedperiodof time,chargethe batterywith an automotive-type12-voltchargerfor a minimumof one hourat six amps. Batteriesgiveoff an explosivegas whilecharging.Chargebatteryin a well ventilatedarea and keepawayfrom an open flame or pilot light as on a waterheater,space heater,furnace,clothesdryeror other gasappliances. Cleaning the Battery Cleanthe batteryby removingitfrom the tractorand washingwith a bakingsoda andwater solution.If necessary,scrapethe battery terminalswith a wire brushto removedeposits.Coatterminalsand exposedwiringwith greaseor petroleumjellyto preventcorrosion. Seat After adjustingthe seat or beforedrivingthetractor,make surethat the seat adjustmentleveris engagedin the seat indexplateand that the seat will not move.Do notadjustthe seatwhilethe tractor is beingdriven.Adjustingthe seat whilethe tractoris movingcould causethe operatorto losecontrolof the tractor. 1. Whilesitting in the seat,graspthe seatadjustmentleveron the Idt sideof the seat and pull it upwardto disengagefrom the seat indexplate. See Figure14. f Battery Failures Somecommoncausesfor batteryfailureare: • Incorrectinitialactivation• undercharging • Overcharging• corrodedconnections • Freezing Thesefailuresare NOTcoveredby yourtractor'swarranty. CHECKING MAIN HARNESS FUSE • A 20 ampfuse is installedin yourtractor'swiringharnessto protectthe tractor'selectricalsystemfrom damagecausedby excessiveamperage. • If theelectricalsystemdoesnot function,or yourtractor'sengine will notcrank,first checkto be certain that thefuse hasnot blown. • Thefuse can be foundinsideof the dashpanel behindthe battery tray.You may needto removethe batteryto gain accessto the fuse.Alwaysusea fuse with the sameamperagecapacityfor replacement. NOTE:A secondfuse holder canbe foundinsidethedash panel.This fuse holderisusedfor the optional12volt poweroutlet. ADJUSTMENTS Neverattemptto makeanyadjustmentswhilethe engineis running, exceptwherespecifiedin theoperator'smanual.Disconnectspark plugwire(s) beforeperforminganyadjustments,repairsor maintenance. Steering and Transmission Linkage Thesteeringtie rod and drag links and the relatedtransmissionlinkage are set at the factoryand shouldnot requirefurtheradjustment. Becauseof the complexadjustmentprocedure,the steeringand transmissionlinkageshouldonlybe servicedor adjustedby a qualified mechanic.If youexperienceproblemswith steering,or with the IVT transmission,contactyournearestSearsParts& RepairService Centerto havethetractorinspected. Figure14 2. Slidethe seat to thedesiredposition.See Figure14. 3. Oncethe desiredpositionis reached,releasetheseat lever.Slide the seat slightlybackand forth as necessaryto engagetheseat leverinto one of theeight adjustmentpositionsin the indexplate. Makecertainthe seat is lockedin position. Side to Side Leveling the Deck NOTE:Checkthe tractor'stire pressurebeforeperforminganydeck levelingadjustments.Referto "Tires"earlier in this sectionfor information regardingtire pressure. If the cuttingdeck appearsto be mowingunevenly,a sideto side adjustmentcan be performed.Adjust if necessaryas follows: 1. With the tractorparkedon a firm, levelsurface,movethe deck to the mid heightposition(thirdor fourth notch)usingthe deck lift lever.Rotatethe left bladeso that it is perpendicularto the tractor frame.Measureand recordthe distancefrom the outsideof the left bladetip to the ground. 2. Movingto the otherside of thetractor,rotatethe right bladeso that it is perpendiculartothe tractorframe,and measurethe distancefrom its outerbladetip to theground. 3. Bothmeasurementstaken shouldbe approximatelyequal. If they'renot, notewhetherthe left side of the deck is loweror higherand proceedto the next step. 23