HP XP20000/XP24000 HP StorageWorks XP24000/XP20000 Disk Array Site Preparation - Page 36

Controlling dust and pollution, Full array, DKC and 4 DKUs, Each DKU, Parameter, Second Rack

|

View all HP XP20000/XP24000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 36 highlights

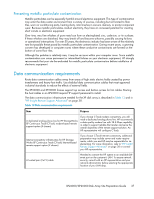

Parameter DKC Each DKU Full array (1 DKC and 4 DKUs) Max. BTUs per hour Max. kcal per hour 21997 5543 21406 5394 107623 27120 Table 11 XP20000 maximum heat and power specifications Parameter Power consumption (kVA) Heat dissipation (kW) BTUs per hour Kcal per hour Primary Rack 4.2 4.0 13702 3453 Second Rack 3.0 2.9 9788 2467 Full array 7.2 6.9 23490 5919 Table 12 shows the disk array's air flow requirements. Table 12 Air flow specifications XP24000/XP20000 Disk Arrays Product number Description Air flow (cubic meters/minute) AE131A AE173A AE191A AE194A AE196A HP XP24000 Disk Control Frame (DKC) 34 HP XP24000 Disk Array Frame (DKU) 32 HP XP20000 DKC Disk Control Unit 4.3 HP XP20000 SVP/Battery Chassis 1.3 HP XP20000 Disk Chassis 5 Cooling airflow for the XP24000 is air intake at front and rear and hot air exhaust out the top. Therefore, the XP24000 is not suitable in a hot isle containment system. XP20000 cooling airflow has air intake at front and hot air exhaust out the rear. Therefore, the XP20000 is suitable in hot isle containment system. Controlling dust and pollution Airborne contaminants and particles of a certain size and hardness can damage the system. Some of the most common contaminants are dust, smoke, ash, corrosive gases and corrosive particulate. Mechanical filters on the disk array protect it by trapping large dust particles. Smaller particles can pass through most filters, and can eventually cause problems in mechanical parts and electrical contacts. Prevent small dust particles from entering the computer room by maintaining its air conditioning system at a high static air pressure level. Your HP representative can help you determine if you need to be concerned about airborne contaminants including gaseous chemical contaminants. HP strongly recommends your site be evaluated for metallic particulate contamination and gaseous chemical contaminants for sites with suspect air quality concerns. Evaluation should be done before the system is installed and periodically monitored. 36 Site requirements for the HP Disk Arrays