HP XP20000/XP24000 HP StorageWorks XP24000/XP20000 Disk Array Site Preparation - Page 62

Required tools, Packaging configurations, Unpacking procedure

|

View all HP XP20000/XP24000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 62 highlights

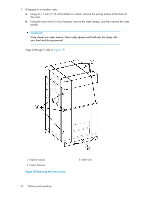

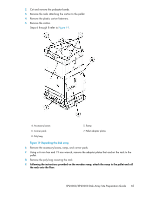

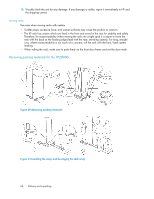

Required tools • Claw hammer (if full packaging with wooden crate) • Open-end or socket wrench 11mm (7/16 in) , 12mm (8/16 in), 14mm (9/16 in), and 17mm (11/16 in), or adjustable wrench • Scissors or box knife to cut polyester banding • Safety glasses • Short stepladder (helpful, but not required) Packaging configurations XP disk array racks are shipped in one of three standard packaging configurations: • Environmental pack (XP24000 only)- consists of stretch wrap over corner protectors. No special tools or procedures are required to unpack shipments in this form. This packaging is used for most shipments within the USA that are direct from the factory to the customer. HP uses special carriers with a dedicated fleet of trucks and specially trained personnel. • Full packaging - consists of a pallet, wooden loading ramp, inner packaging, and outer corrugated carton assembly. • Full packaging with wooden crate - consists of full packaging encased in a wooden crate. Unpacking procedure If you need to unpack the equipment without HP supervision, follow the instructions in this section. CAUTION: Be very careful when handling the equipment. Do not drop the equipment from a height of more than 0.5 cm (0.2 inch). Floor unevenness must be less than 1 cm (0.4 inch). WARNING! The equipment racks are very heavy. To avoid injury, use appropriate lifting tools and have three people unpack and move the equipment. CAUTION: Any movement of the equipment by forklift should be done prior to unpacking. The carton assembly provides the most secure support of the equipment during movement. Transporting the equipment by forklift after the packaging carton has been removed is not advisable. CAUTION: The equipment racks are top heavy and contain very sensitive electronic and mechanical components. When moving on frame casters, the rolling surface must be able to support the equipment weight and must be free of surface conditions that could cause shock or vibration to the rack contents. 62 Delivery and unpacking