Kyocera KM-2050 1650/2050/2550 Operation Guide (Advanced) - Page 150

Paper, Basic Specifications of Paper, Proper Paper Selection - drum unit

|

View all Kyocera KM-2050 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 150 highlights

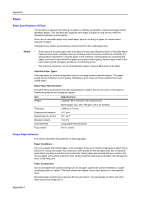

Appendix Paper Basic Specifications of Paper This machine is designed for printing on paper for ordinary xerographic copiers and page printers (standard paper). This machine also supports other types of paper as long as they meet the standards explained in this chapter. Since use of unsuitable paper may cause paper jams or wrinkling of paper, be careful about selection of paper. Transparencies, labels, and envelopes must be fed from the multi-bypass tray. Notes • Some types of recycled paper may not satisfy the basic specifications shown in the table below because some basic conditions such as moisture content and pulp content do not satisfy the specifications required for using the paper in this machine. Consequently, for using recycled paper, purchase a small amount of paper and perform trial copying. Select a type of which the print result is good and paper powder is not extremely much. • For problems caused by use of off-specification paper, Kyocera Mita shall not be liable. Available Paper Types Use copy paper for normal xerographic copiers and page printers (standard paper). The paper quality has an influence on print quality. Satisfactory print result cannot be obtained from poor quality paper. Basic Paper Specifications The table below summarizes the basic specifications of paper that can be used in this machine. Details are given on the subsequent pages. Item Weight Thickness Dimensional tolerance Squareness of corners Moisture content Grain direction Pulp content Specifications Cassette: 60 to 105 g/m² (16 to 28 lb/ream) Multi-bypass tray: 45 to 160 g/m² (12 to 42 lb/ream) 0.086 to 0.110 mm ±0.7 mm 90 ° ±0.2 ° 4 to 6 % Long (paper feed direction) 80 % or more Proper Paper Selection This section describes the guideline for selecting paper. Paper Conditions Do not use paper with folded edges, curls, smudges, tears, lint or surface roughness or paper that is easily torn. Using such paper may cause poor print quality as well as paper jams due to improper paper feed, resulting in shortening of product life. Select paper with smooth and even surface. Do not use paper with surface coating or other surface treatment because such paper may damage the drum or the fixing unit. Paper Composition Do not use paper with surface coating such as art paper, paper with surface treatment, or paper containing plastic or carbon. The heat causes such paper to emit toxic gases or to damage the drum. Standard paper should have at least an 80 % pulp content. The percentage of cotton and other fibers should not exceed 20 %. Appendix-2