Lexmark 2050 Color Jetprinter Service Manual - Page 25

Transport Service Check, Diagnostic Information 2-15

|

View all Lexmark 2050 Color Jetprinter manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

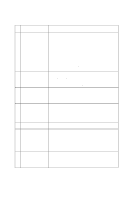

Transport Service Check FRU Action 1 Transport Motor Check the motor for binds, or loose motor pulley. Disconnect the transport motor (J6) from the system board. Check for 8 to 18 ohms between pins 2 and 3 on the motor cable. If the reading is incorrect, replace the motor. Check for motor pins shorted to the motor housing. If you find a pin shorted to the housing, replace the motor. If the failure remains, replace the system board. 2 System Board Turn the printer off and disconnect J6 from the system board. Turn the printer on and check for a pulse of 6 to 8 V dc between J6-2 and ground as the printer goes through POST. 3 Carrier Guide Rod Clean the carrier rod. 4 Transport Belt Idler Pulley Parts Carrier Frame 5 Encoder Strip Lubricate the rod or the carrier rod bearing surface with grease P/N 1329301. Check for worn, loose or broken parts. Check for obstructions blocking carrier movement. Carrier to carrier frame engagement should be lubricated with grease P/N 1329301. Check for wear and dirt. 6 Printhead Cable Be sure connector J4 is fully seated. Check the cable for damage. Encoder Strip Encoder Card System Board 7 Maintenance Station Perform the 'Encoder Sensor Test' on page 3-1. If you cannot enter the test, replace the system board. A problem with the maintenance station can cause carrier movement problems at the right margin. Go to the 'Maintenance Station Service Check' on page 2-7. Diagnostic Information 2-15