Lexmark 7000 Color Jetprinter Service Manual - Page 27

Diagnostic Information 2-14, Paper Feed

|

View all Lexmark 7000 Color Jetprinter manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

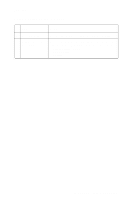

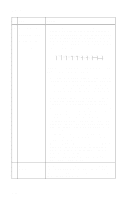

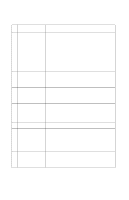

4092-001 FRU 5 Paper Feed 6 Transport 7 Alignment Action Ink smudging and smearing can be caused by paper problems or problems in the paper feed area. Check the following: • Correct type of paper is being used. • Paper for curl or wrinkles. • Feed rollers for wear, dirt, or looseness. • Gears for wear or binds. • Paper path for obstructions. Blurred print and voids can be caused by problems in the transport area. Check the following: • Transport belt for wear and full engagement into the carrier grip. • Carrier guide rod for wear or dirt. • Carrier to carrier frame engagement should be lubricated with grease P/N 1329301. Lubricate the carrier guide rod and carrier frame on both sides where the two top bearing surfaces ride on the frame. • Idler pulley parts for wear, damage, or looseness. • Encoder strip for wear or dirt. Uneven vertical lines can be adjusted by performing the bidirectional alignment. The user is directed, through the Printer Control program, to perform the head to head and bidirectional printing alignments, when replacing a print cartridge. Diagnostic Information 2-14