Lexmark X342N Service Manual - Page 41

Service checks - user guide

|

UPC - 734646256292

View all Lexmark X342N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 41 highlights

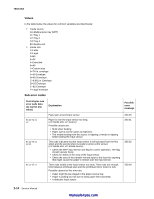

7003-XXX Service checks Service checks which involve measuring voltages on the LVPS/HVPS (low voltage power supply/ high voltage power supply board) should be performed with the MFP positioned on its back side. Note: When you make voltage readings, always use frame ground unless another ground is specified. See the wiring diagram in the back of the book for more information. ADF service check FRU ADF ADF card Controller card ADF pick pad ADF separator roller ADF paper tray and extender. ADF cover Action Ensure that the proper paper size is being used in the ADF. Are the paper guides on the ADF tray properly adjusted? Inspect the ADF separator roll and ADF separator pad for wear. If they are worn, replace them. If excessive jamming occurs at the white mylar sheet located at the bottom of the ADF unit, replace the ADF unit. Inspect the paper present and paper position sensors on the ADF. • Check for dirt in the sensors. Clean if needed. • Check the flags on the sensor. Are they able to move freely? If the sensor flags are damaged, replace the sensor assembly. If the sensor flags are ok, check to see if they are properly connected to the ADF card (located in the ADF). Replace sensor assembly if needed. Make sure the ADF cable is securely connected to the ADF card and the controller card. If the cable is properly connected, perform the following checks: • Check the ADF cable for continuity. • Check pin 15 on controller card connector J3 for +5V. • Check pin 19 on controller card connector J3for +24V. • Pins 6,14,17,18,20,and 22 should be ground. If voltages are present, replace the ADF card. If that does not fix the problem, replace the ADF. If replacing the ADF does not fix the problem, replace the controller card. If the ADF is multi feeding, check the ADF pick roller and pad for dirt. Remove them from the MFP, and clean them with a lint free cloth and isopropyl alcohol. If the leading edge of the paper is damaged, instruct the user to lessen the number of documents being copied from the ADF at one time. If thin, glossy paper, or carbon forms are used in the ADF, use the high friction pick pad (40X3499). If there are excessive misfeeds from the ADF, verify the the ADF paper tray and extender are properly installed. Skews and jams at the ADF paper present sensor might be caused by an improperly closed ADF cover. Ensure the ADF cover is closed properly. Diagnostic information 2-19