Poulan PP4218A Instruction Manual - Page 17

Replace Fuel Filter, Chain Adjustment, Chain Sharpening, Tools Required, To Sharpen Chain - spark plug gap

|

View all Poulan PP4218A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

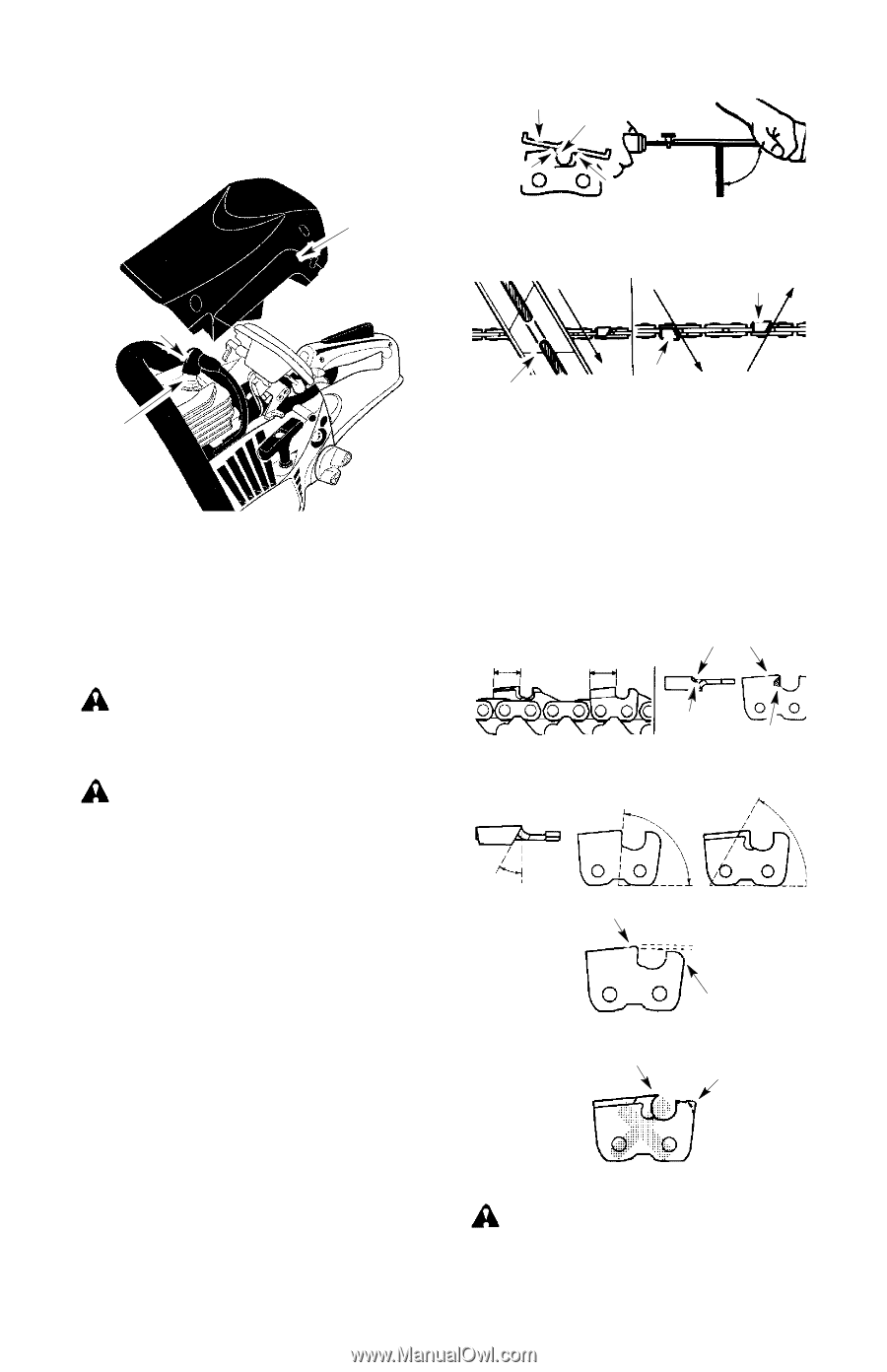

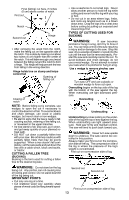

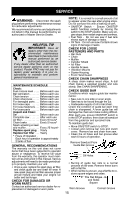

5. Replace with Champion RCJ- 7Y or Torch R7 spark plug and tighten securely with a 3/4 inch (19 mm) socket wrench. Spark plug gap should be 0.025 inch (0,6 mm). 6. Reinstall the spark plug boot. 7. Reinstall the cylinder cover and 3 screws. Tighten securely. Cylinder Cover Spark Plug Boot NOTE: The chain has both left and right hand cutters. File Holder File Cutter 90° Depth Gauge S Align the 30° file holder marks parallel with the bar and to the center of the chain. Cutter Spark Plug REPLACE FUEL FILTER To replace fuel filter, drain your unit by running it dry of fuel. Remove fuel cap and its connected retainer from tank. Pull filter from tank and remove from line. Replace and reassemble. CHAIN ADJUSTMENT See CHAIN TENSION in ASSEMBLY section. CHAIN SHARPENING WARNING: Improper chain sharp- ening techniques and/or depth gauge maintenance will increase the chance of kickback which can result in serious injury. WARNING: Wear protective gloves when handling chain. The chain is sharp and can cut you even when it is not moving. Conditions which indicate the need for chain sharpening: S Reduction in size of wood chips. The size of the wood chip will decrease as the chain gets duller until it becomes more like a powder than a chip. Note that dead or rotted wood will not produce a good chip. S Saw cuts to one side or at an angle. S Saw has to be forced through the cut. Tools required: S 5/32 inch (4 mm) diameter round file and file holder S Flat file S Depth gauge tool TO SHARPEN CHAIN: 1. Move ON/STOP switch to the STOP position. 2. Check chain for proper tension. Adjust chain tension if necessary. See CHAIN TENSION section. 3. Sharpen cutters. S To sharpen the cutters, position the file holder level (90° ) so that it rests on the top edges of the cutter and depth gauge. 30° Cutter File Holder Line S Sharpen cutters on one side of the chain first. File from the inside of each cutter to the outside. Then, turn the chain saw around and repeat the pro- cess for the other side of the chain. S File on the forward stroke only. Use 2 or 3 strokes per cutting edge. S Keep all cutters the same length when filing. S File enough to remove any damage to cutting edges (side plate and top plate of cutter). All Cutters Remove Damage Same Length Top Plate Side Plate S File chain to meet the specifications as shown. 80° 60° 30° Hook Angle 0.025 inch (0.65 mm) Right Too Much Hook Angle Rounded Corner Squared Off Corner Wrong WARNING: Maintain the proper hook angle according to the manufacturer's specifications for the chain you are using. Improper hook angle will increase the chance of kickback which can result in serious injury. 17