Poulan PP4218A Instruction Manual - Page 8

CHAIN TENSION Including units, with chain already installed, Checking the tension, Adjusting

|

View all Poulan PP4218A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

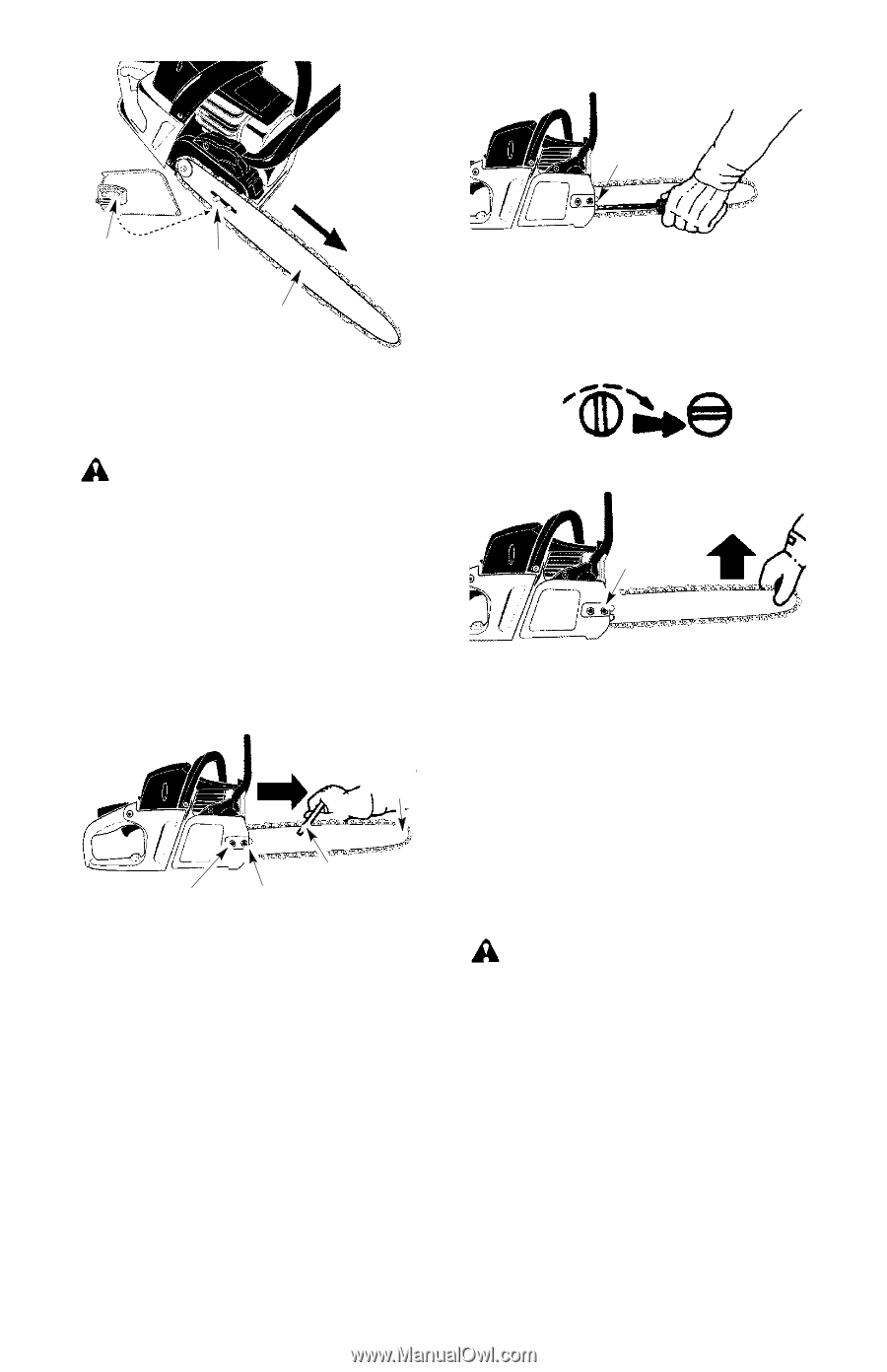

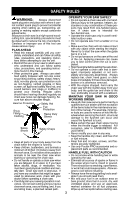

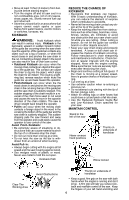

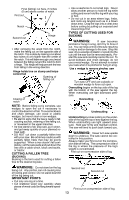

Clutch Cover 2. Turn adjusting screw clockwise until chain solidly contacts bottom of guide bar rail. Adjusting Screw Adjusting Pin Lower Hole Guide Bar 12. Install bar nuts and finger tighten only. Once the chain is tensioned, you will need to tighten bar nuts. CHAIN TENSION (Including units with chain already installed) WARNING: Wear protective gloves when handling chain. The chain is sharp and can cut you even when it is not moving. NOTE: When adjusting chain tension, make sure the chain brake nuts are finger tight only. Attempting to tension the chain when the chain brake nuts are tight can cause damage. Checking the tension: Use the screwdriver end of the chain adjustment tool (bar tool) to move chain around guide bar. If the chain does not rotate, it is too tight. If the chain is too loose, it will sag below the bar. Guide Bar Bar Nuts Chain Adjustment Adjusting Screw Tool (Bar Tool) Adjusting the tension: Chain tension is very important. Chains stretch during use. This is especially true during the first few times you use your saw. Always check chain tension each time you use and refuel your saw. 1. Loosen bar nuts until they are finger tight against the clutch cover. 3. Using bar tool, roll chain around guide bar to ensure all links are in bar groove. 4. Lift up tip of guide bar to check for sag. Release tip of guide bar, then turn adjusting screw 1/4 turn clockwise. Repeat until sag does not exist. Adjusting Screw - 1/4 Turn 5. While lifting tip of guide bar, tighten bar nuts securely with the bar tool. Bar Nuts 6. Use the screwdriver end of the bar tool to move chain around guide bar. 7. If chain does not rotate, it is too tight. Slightly loosen bar nuts and loosen chain by turning the adjusting screw 1/4 turn counterclockwise. Retighten bar nuts. 8. If chain is too loose, it will sag below the guide bar. DO NOT operate the saw if the chain is loose. NOTE: The chain is tensioned correctly when the weight of the chain does not cause it to sag below the guide bar (with the chain saw sitting in an upright position), but the chain still moves freely around the guide bar. WARNING: If the saw is operated with a loose chain, the chain could jump off the guide bar and result in serious injury to the operator and/or damage the chain making it unusable. If the chain jumps off the guide bar, inspect each drive link for damage. Damaged chain must be repaired or replaced. 8