Ridgid KJ-3100 Owners Manual - Page 10

KJ-2200/KJ-3100 Water Jetting Machines

|

View all Ridgid KJ-3100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

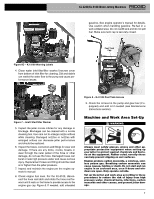

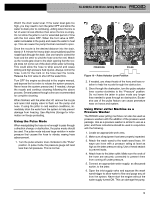

KJ-2200/KJ-3100 Water Jetting Machines 1. Check work area for: • Adequate lighting. • Flammable liquids, vapors or dust that may ignite. If present, do not work in area until sources have been identified and corrected. The jetter is not explosion proof and can cause sparks. • Clear, level, stable dry place for machine and operator. If needed, remove the water from the work area. Wood or other coverings may need to be put down. • Jetter location that is in a well ventilated outdoor area. Do not place the jetter indoors, even with doors and windows open. Jetter can be located remotely from the point of use. • Suitable water supply. • Clear path to transport the jetter to the set up location. 2. Inspect the drain to be cleaned. If possible, determine the access point(s) to the drain, the size(s) and length(s) of the drain, distance to tanks or mainlines, the nature of the blockage, presence of drain cleaning chemicals or other chemicals, etc. If chemicals are present in the drain, it is important to understand the specific safety measures required to work around those chemicals. Contact the chemical manufacturer for required information. If needed, remove fixture (water closet, etc.) to allow access to the drain. Do not feed the hose through a fixture. This could damage the hose and the fixture. 3. Determine the correct equipment for the application. See the Specifications section for information on these jetters. Drain cleaners and jetters for other applications can be found by consulting the RIDGID Catalog, on line at www.RIDGID.com or www.RIDGID.eu 4. Make sure all equipment has been properly inspected. 5. Evaluate the work area and determine if any barriers are needed to keep bystanders away. Bystanders can distract the operator. If working near traffic, erect cones or other barriers to alert drivers. 6. If needed, place protective covers in the work area. The drain cleaning process can be messy. 7. Take the jetter to the well-ventilated outdoor work area along the clear path. If the machine needs to be lifted, use proper lifting techniques. Use care moving equipment up and down stairs, and be aware of possible slip hazards. Wear appropriate footwear to help prevent slips. Water Supply Confirm that there is sufficient water flow for jetter. Run a 8 hose from the water source to the jetter. Use the largest diameter, shortest length hose possible. A 3/4" I.D. hose is the minimum recommended size. An appropriate backflow prevention device should be used to comply with all local codes and ordinances. Turn the water on at the source and measure the time it takes to fill a clean five gallon bucket. See the following table for maximum bucket fill times for each jetter. Jetter KJ-2200 KJ-3100 GPM Rating 2.4 5.5 Maximum 5 Gallon Bucket Fill Time 125 seconds 55 seconds Insufficient water flow will prevent the jetter from reaching the pressure rating and could damage the pump. Inspect the water in the bucket for dirt and debris. Dirt and debris in the water supply can cause excess pump wear, clog the jetter filters nozzles and reduce performance. Do not use water from ponds, lakes or other sources that may be contaminated. In cases of insufficient water flow, possible solutions include using fittings to allow multiple supply hoses to be connected to the jetter or the use of a tank. If a tank is used, plumb a tee with full port valves to the jetter water inlet as shown in Figure 9. Connect a 3/4" (19 mm) hose no longer than 6 feet (1.8 m) to the valve on the outlet of the tee, and connect the water supply to the run of the tee. Either place the hose end in the tank or connect to the tank outlet. The entire length of the tank hose should be no more than 5" (12.7 cm) above the jetter water inlet, or the jetter will not draw water from the tank. Water In To Jetter Inlet Filter Hose To Tank Tee Full Port Valve Water Supply In Figure 9 - Water Supply Connections When Using A Tank