Ridgid KJ-3100 Owners Manual - Page 9

Machine and Work Area Set-Up

|

View all Ridgid KJ-3100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

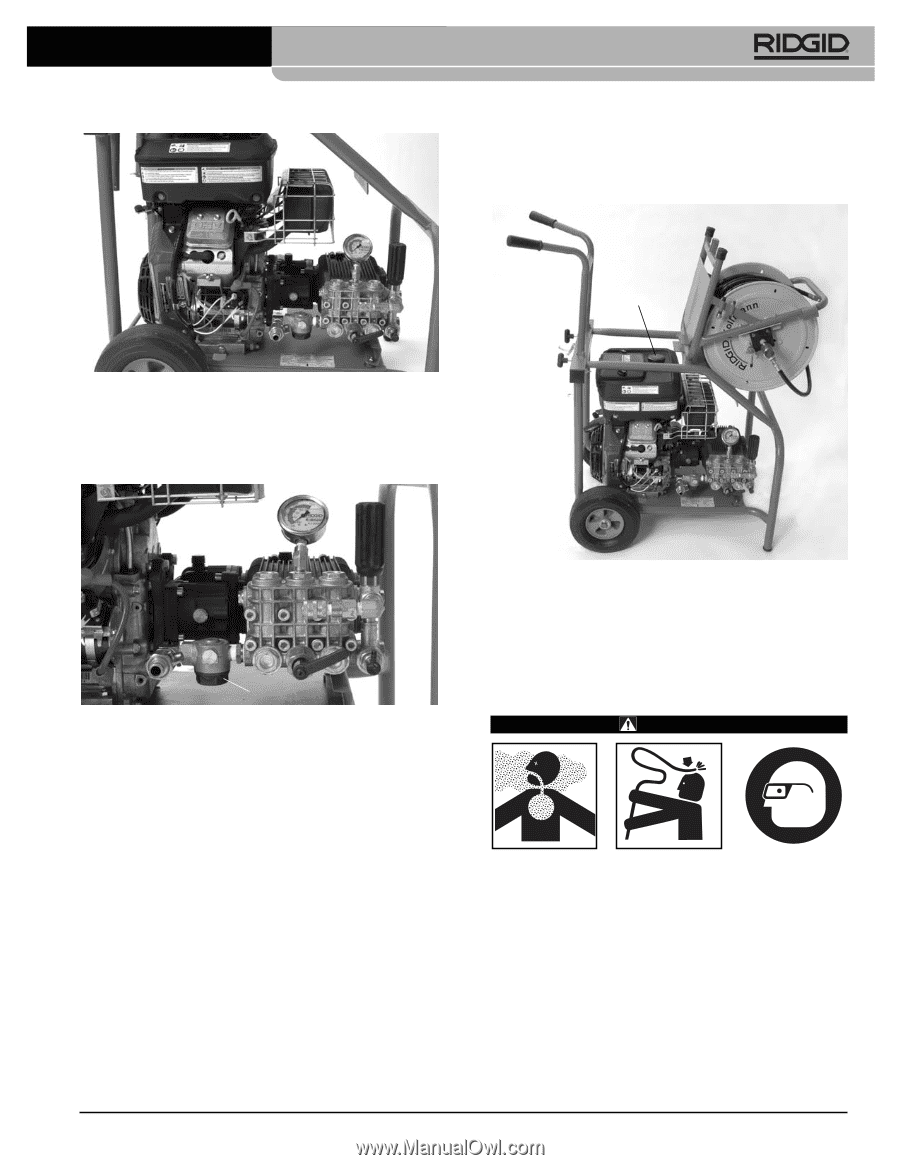

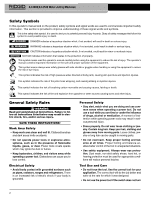

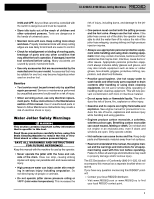

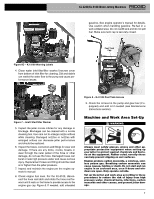

KJ-2200/KJ-3100 Water Jetting Machines gasoline. See engine operator's manual for details. Use caution when handling gasoline. Re-fuel in a well ventilated area. Do not overfill tank and do not spill fuel. Make sure tank cap is securely closed. Figure 6D - KJ-3100 Warning Labels 4. Clean water inlet filter/filter washer.Unscrew cover from bottom of inlet filter for cleaning. Dirt and debris can restrict the water flow to the pump and cause performance issues. Fuel Tank Cap Filter Figure 7 - Inlet Filter/Filter Washer 5. Inspect the jetter nozzle orifices for any damage or blockage. Blockages can be cleaned with a nozzle cleaning tool. Use care not to enlarge nozzle orifices while cleaning. Damaged nozzles or nozzles with enlarged orifices can decrease jetter performance and should be replaced. 6. Inspect the hoses, connectors and fittings for wear and damage. If there are any kinks, cracks, breaks or wear through the outer jacket of the hose or other damage, do not use the hose. Damaged hoses can burst or leak high pressure water and cause serious injury. Replacement hoses and fitting should be rated at or higher than the jetter pressure. 7. Inspect and maintain the engine per the engine operator's manual. 8. Check engine fuel level. For the KJ-3100, disconnect the hose reel latch and rotate the hose reel forward until it rests on the frame to provide access to the engine gas cap Figure 8. If needed, add unleaded Figure 8 - KJ-3100 Fuel Tank Access 9. Check the oil level in the pump and gear box (if equipped) and add oil if needed (see Maintenance Instructions section). Machine and Work Area Set-Up WARNING Always wear safety glasses, gloves and other appropriate protective equipment when setting up your jetter to protect against chemicals and bacteria on the equipment. Rubber soled, non-slip shoes can help prevent slipping on wet surfaces. Engines produce carbon monoxide, a colorless, odorless poison gas. Breathing carbon monoxide can cause nausea, fainting or death. Do not start and run engine in an enclosed area, even if doors and windows are open. Only operate outside. Set up the jetter and work area according to these procedures to reduce the risk of injury from high pressure water, chemical burns, infections, carbon monoxide and other causes, and prevent jetter damage. 7