Ridgid KJ-3100 Owners Manual - Page 19

Troubleshooting - water jetter troubleshooting

|

View all Ridgid KJ-3100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

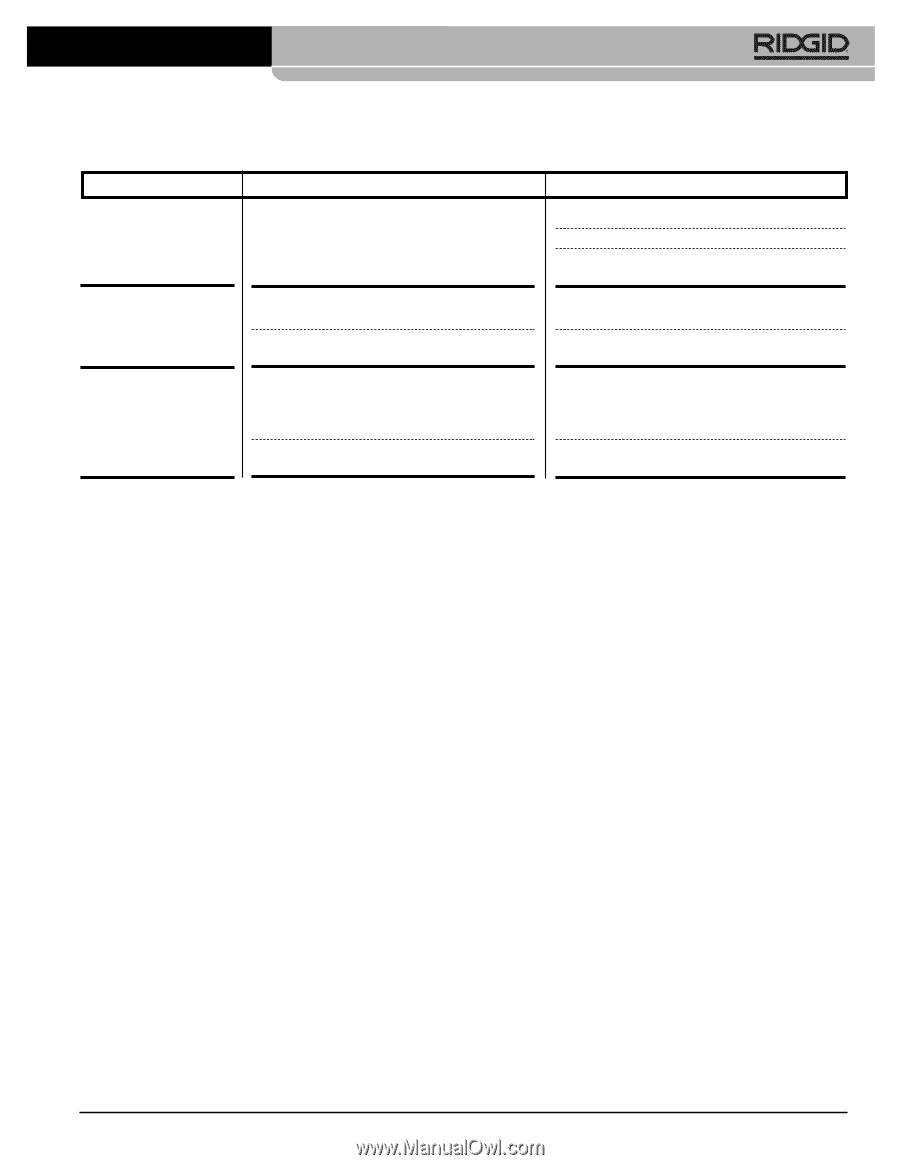

KJ-2200/KJ-3100 Water Jetting Machines Troubleshooting PROBLEM CAUSE Jetter runs but produces Inadequate water supply. little or no pressure. Jetter will not adjust to full operating pressure at start-up. Air is trapped in system. Jetter nozzle thrusters are blocked. Jetter pressure gage oscillates from 500 to full operating pressure. Jetter nozzle thrusters are blocked. Debris or air trapped in system. CORRECTION Make certain water supply faucet is ON. Make certain jetter's water supply inlet valve is ON. Make certain water supply hose is clear and not kinked or collapsed. Remove nozzle from jet hose and run jetter to flush air/debris from system. Remove nozzle and clean thruster orifices with nozzle cleaning tool. Remove nozzle. Use nozzle cleaning tool to clear nozzle orifices: select proper wire size and push completely through each thruster orifice to remove debris. Remove nozzle and insert jet hose in drain line. Run jetter to flush trapped air or debris. 17