Ridgid KJ-3100 Owners Manual - Page 13

Operating Instructions

|

View all Ridgid KJ-3100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

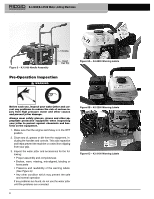

KJ-2200/KJ-3100 Water Jetting Machines Operating Instructions WARNING Always wear eye protection to protect your eyes against dirt and other foreign objects. Always wear appropriate personal protective equipment for the work environment. Never operate the jetter with the hose end outside of the drain. Hose can whip, causing striking injuries and spray can penetrate skin and cause serious injury. High pressure fluid can inject under skin resulting in serious injury, including amputation. Do not direct spray at people or animals. Do not operate jetter above pressure rating or 140°F (inlet water temperature). This increases the risk of injury, including burns, and damage to the jetter. One person must control both the jetting process and the foot valve. Always use the foot valve. If the jetter hose comes out of the drain, the operator must be able to shut the water flow off to reduce the risk of the jetter hose whipping, causing striking and high pressure injection injuries. Always use appropriate personal protective equipment while handling and using drain cleaning equipment. Drain may contain chemicals, bacteria and other substances that may be toxic, infectious, cause burns or other issues. Appropriate personal protective equipment always includes safety glasses and gloves, and may also include equipment such as latex or rubber gloves, face shields, goggles, protective clothing, respirators, and steel toed footwear. Follow operating instructions to reduce the risk of injury from whipping hoses, high pressure liquid injection, carbon monoxide and other causes. 1. Make sure that machine and work area is properly set up and that the work area is free of bystanders and other distractions. If the jetter is located remotely from the point of use, another person should be located at the jetter. 2. Insert the hose with nozzle attached into the drain at least three feet so that the end of the hose will not come out of the drain and whip around when the machine is started. 3. Confirm that the pulse actuator lever is rotated counter-clockwise in the "Pressure" position (Figure 16). 4. Open the inlet supply valve. Never start the engine without the water supply turned ON. This can damage the pump. 5. Press the foot valve to reduce pressure and allow the engine to start. Confirm that water flows freely through the nozzle. Following the starting instructions supplied in the engine manual, start the engine. Allow the engine to warm up. Unloader Valve Pressure Gauge Thermal Overload Pulse Actuator Figure 13 - Controls 6. Turn the unloader valve while monitoring the pressure gauge to adjust the pressure as desired (clockwise to increase pressure, counter-clockwise to decrease pressure). Do not exceed the machine pressure rating being used. Do not force the unloader valve or use wrenches or tools to turn. This will damage the unloader valve. Jetter KJ-2200 KJ-3100 Pressure Rating 2200 psi 3000 psi If the jetter will not generate the rated pressure or is erratic • Make sure the engine throttle is properly adjusted. • Make sure that the inlet supply valve is fully open and other valves in the supply system are fully open. • Turn unloader valve clockwise to increase pressure. Do not force. • Make sure the pulse actuator is on the "Pressure" setting. • Cycle the pulse actuator between the "Pressure" and "Pulse" position several times while the unit is running to clear any trapped air from the system. 11