Ryobi RTS23 User Manual 5 - Page 23

Cutting Aids, Caution, Auxiliary Fence, How To Make And Attach An Auxiliary, Fence, Cutting,

|

View all Ryobi RTS23 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 23 highlights

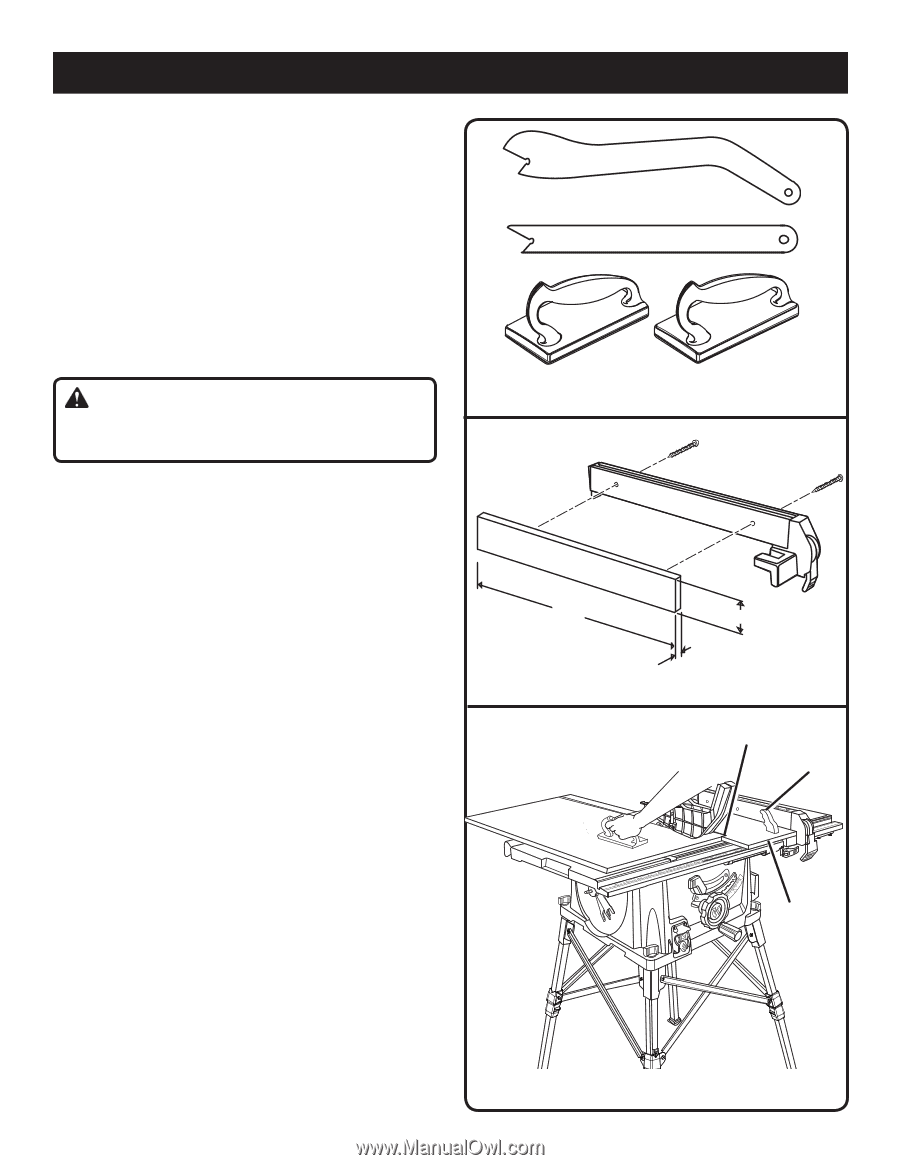

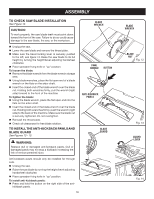

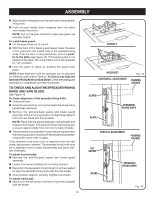

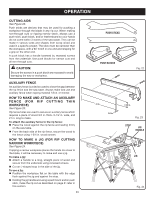

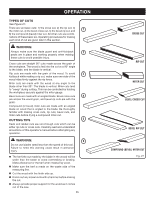

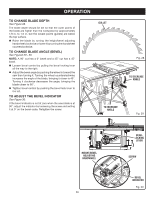

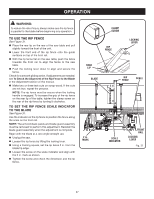

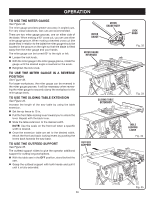

OPERATION CUTTING AIDS See Figure 22. Push sticks are devices that may be used for pushing a workpiece through the blade in any rip cut. When making non-through cuts or ripping narrow stock, always use a push stick, push block, and/or featherboard so your hands do not come within 3 inches of the saw blade. They can be made in various sizes and shapes from scrap wood and used in a specific project. The stick must be narrower than the workpiece, with a 90˚ notch in one end and shaping for a grip on the other end. A push block has a handle fastened by recessed screws from the underside. Use push blocks for narrow cuts and all non-through cuts. CAUTION: Be sure the screws in a push block are recessed to avoid damaging the saw or workpiece. AUXILIARY FENCE An auxiliary fence is a device used to close the gap between the rip fence and the saw table. Always make and use and auxiliary fence when ripping material 1/8 in. or thinner. HOW TO MAKE AND ATTACH AN AUXILIARY FENCE (FOR RIP CUTTING THIN WORKPIECE) See Figure 23. Rip fence holes are used to secure an auxiliary fence which requires a piece of wood 3/4 in. thick, 3-1/2 in. wide, and 21 in. long to make. To attach the auxiliary fence to the rip fence: Place the wood against the rip fence and resting firmly on the saw table. From the back side of the rip fence, secure the wood to the fence using 1-3/4 in. wood screws. HOW TO MAKE A JIG (FOR RIP CUTTING NARROW WORKPIECE) See Figure 24. If ripping a narrow workpiece places the hands too close to the blade, it will be necessary to make and use a jig. To make a jig: Attach a handle to a long, straight piece of wood and secure from the underside using recessed screws. Cut an L-shaped stop in the side of the jig. To use a jig: Position the workpiece flat on the table with the edge flush against the jig and against the stop. Holding the jig handle and using a push block and/or push stick, make the rip cut as described on page 31 later in this section. 23 PUSH STICKS PUSH BLOCKS Fig. 22 21 in. 3/4 in. 3 1/2 in. Fig. 23 STOP JIG HANDLE JIG Fig. 24