Ryobi RTS23 User Manual 5 - Page 29

Heeling Paralleling The Blade To The, Miter Gauge Groove, Warning

|

View all Ryobi RTS23 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

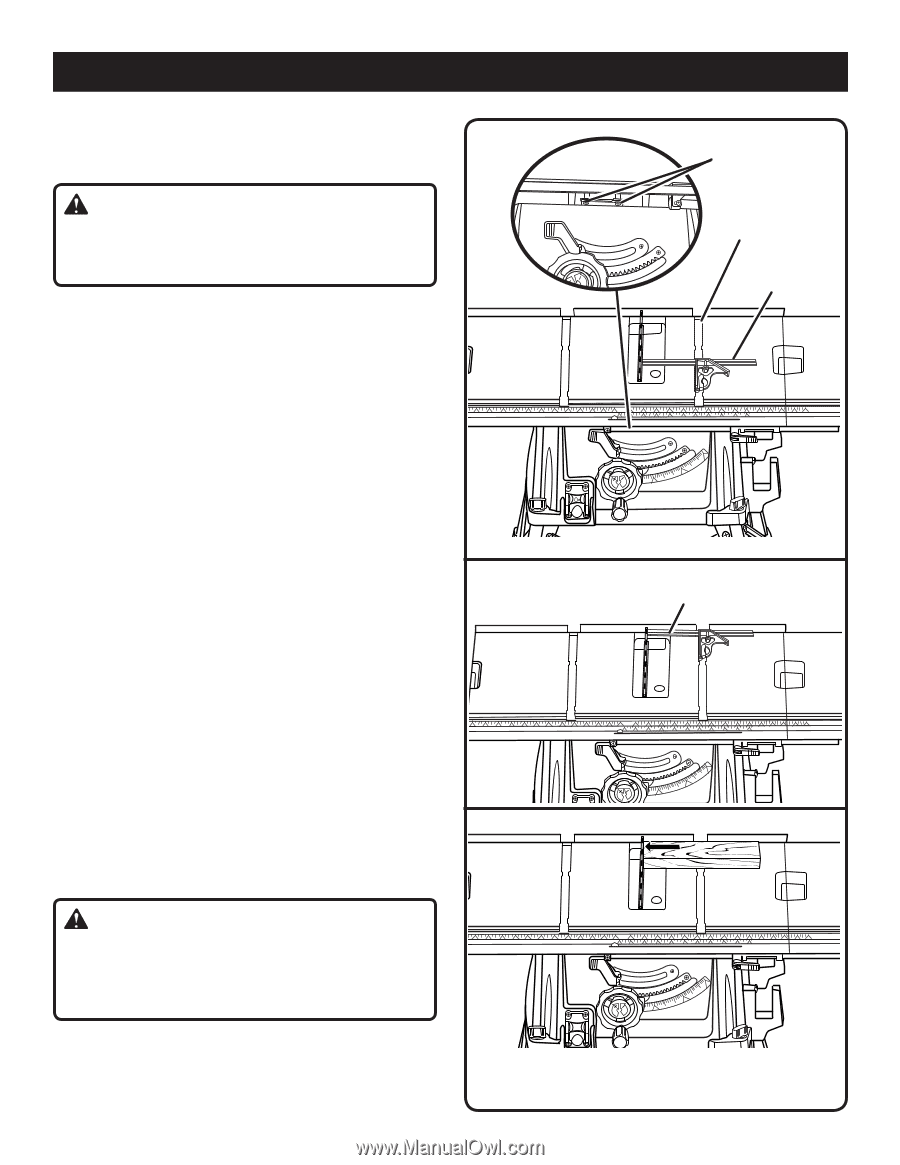

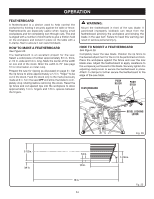

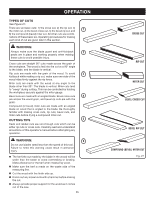

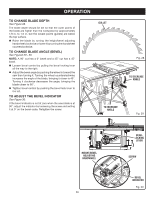

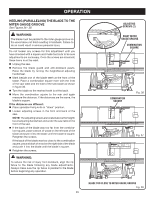

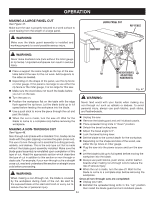

OPERATION HEELING (PARALLELING) THE BLADE TO THE MITER GAUGE GROOVE See Figures 36 - 38. WARNING: The blade must be parallel to the miter gauge groove so the wood does not bind resulting in kickback. Failure to do so could result in serious personal injury. Do not loosen any screws for this adjustment until you have checked with a square and made test cuts to be sure adjustments are necessary. Once the screws are loosened, these items must be reset. Unplug the saw. Remove the blade guard and anti-kickback pawls. Raise the blade by turning the height/bevel adjusting handwheel. Mark beside one of the blade teeth at the front of the blade. Place a combination square even with the front of the saw table and the side of the saw blade as shown in figure 36. Turn the blade so the marked tooth is at the back. Move the combination square to the rear and again measure the distance. If the distances are the same, the blade is square. If the distances are different: Place spreader/riving knife in "down" position. Loosen adjusting screws in the front and back of the saw. NOTE: The adjusting screws are located above the height/ bevel adjusting handwheel and under the saw table in the front of the saw. If the back of the blade was too far from the combination square, place a block of wood on the left side of the blade and push it into the blade until the blade is square. Retighten the screws. If the back of the blade was too close to the combination square, place a block of wood on the right side of the blade and push it into the blade until the blade is square. Retighten the screws. WARNING: To reduce the risk of injury from kickback, align the rip fence to the blade following any blade adjustments. Always make sure the rip fence is parallel to the blade before beginning any operation. ADJUSTING SCREWS (2) RIGHT MITER GAUGE GROOVE COMBINATION SQUARE COMBINATION SQUARE Fig. 36 Fig. 37 BLADE TOO CLOSE TO MITER GAUGE GROOVE Fig. 38 29