Ryobi RTS23 User Manual 5 - Page 34

Warning, Making A Large Panel Cut, Making A Non-through Cut

|

View all Ryobi RTS23 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 34 highlights

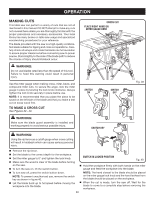

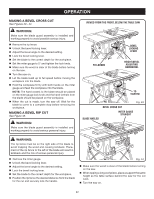

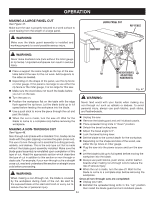

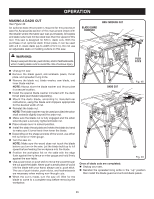

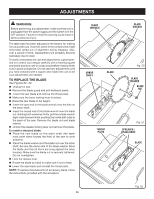

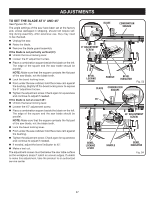

OPERATION MAKING A LARGE PANEL CUT See Figure 47. Make sure the saw is properly secured to a work surface to avoid tipping from the weight of a large panel. LARGE PANEL CUT RIP FENCE WARNING: Make sure the blade guard assembly is installed and working properly to avoid possible serious injury. SUPPORT WARNING: Never make freehand cuts (cuts without the miter gauge or rip fence). Unguided workpieces can result in serious injury. Place a support the same height as the top of the saw table behind the saw for the cut work. Add supports to the sides as needed. Depending on the shape of the panel, use the rip fence or miter gauge. If the panel is too large to use either the rip fence or the miter gauge, it is too large for this saw. Make sure the wood does not touch the blade before you turn on the saw. HEIGHT/BEVEL ADJUSTING HANDWHEEL Fig. 47 Turn the saw on. Position the workpiece flat on the table with the edge flush against the rip fence. Let the blade build up to full speed before feeding the workpiece into the blade. Use a push stick to move the piece through the cut and past the blade. When the cut is made, turn the saw off. Wait for the blade to come to a complete stop before removing the workpiece. MAKING A NON-THROUGH CUT See Figure 48. Non-through cuts (made with a standard 10 in. blade) can be made with the grain (ripping) or across the grain (cross cut). The use of a non-through cut is essential to cutting grooves, rabbets, and dadoes. This is the only type cut that is made without the blade guard assembly installed. Make sure the blade guard assembly is reinstalled upon completion of this type of cut. Read the appropriate section which describes the type of cut in addition to this section on non-through or dado cuts. For example, if your non-through cut is a straight cross cut, read and understand the section on straight cross cuts before proceeding. WARNING: When making a non-through cut, the blade is covered by the workpiece during most of the cut. Be alert to the exposed blade at the start and finish of every cut to reduce the risk of personal injury. WARNING: Never feed wood with your hands when making any non-through cut such as rabbets or dadoes. To avoid personal injury, always use push blocks, push sticks, and featherboards. Unplug the saw. Remove the blade guard and anti-kickback pawls. Place spreader/riving knife in "down" position. Unlock the bevel locking lever. Adjust the bevel angle to 0°. Lock the bevel locking lever. Set the blade to the correct depth for the workpiece. Depending on the shape and size of the wood, use either the rip fence or miter gauge. Plug the saw into the power source and turn the saw on. Let the blade build up to full speed before moving the workpiece into the blade. Always use push blocks, push sticks, and/or feather- boards when making non-through cuts to reduce the risk of serious injury. When the cut is made, turn the saw off. Wait for the blade to come to a complete stop before removing the workpiece. Once all non-through cuts are completed: Unplug your saw. Reinstall the spreader/riving knife in the "up" position then install the blade guard and anti-kickback pawls. 34