Stihl SR 450 Product Instruction Manual - Page 38

Maintenance and Care - replacement tank

|

View all Stihl SR 450 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 38 highlights

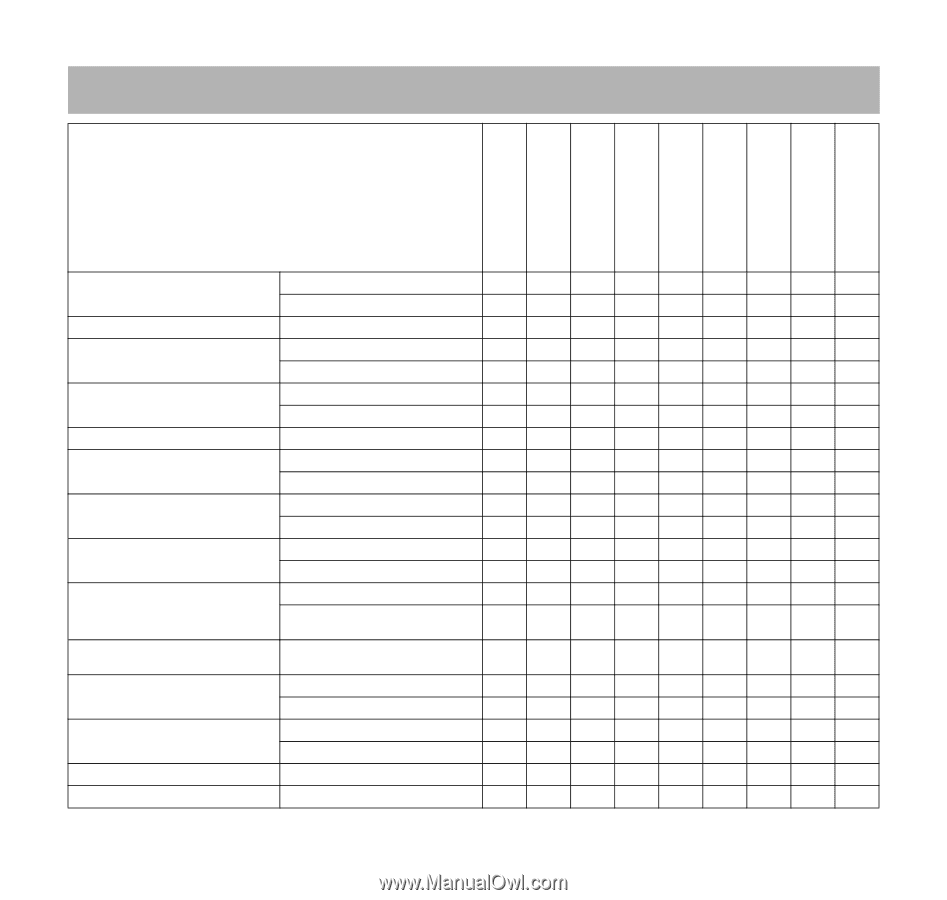

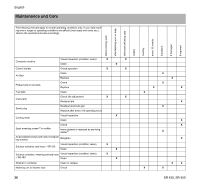

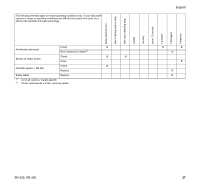

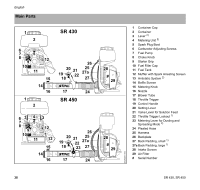

English Maintenance and Care The following intervals apply to normal operating conditions only. If your daily working time is longer or operating conditions are difficult (very dusty work area, etc.), shorten the specified intervals accordingly. before starting work after finishing work or daily after each refueling stop weekly monthly every 12 months if problem if damaged if required Complete machine Visual inspection (condition, leaks) Clean X X X Control handle Check operation X X Air filter Clean Replace Pickup body in fuel tank Check Replace Fuel tank Clean Carburetor Check idle adjustment Readjust idle X X Spark plug Readjust electrode gap Replace after every 100 operating hours Visual Inspection X Cooling inlets Clean Sparl arresting screen1) in muffler Check Have cleaned or replaced by servicing dealer2) All accessible screws and nuts (not adjusting screws) Retighten Solution container and hose - SR 430 Visual inspection (condition, leaks) Clean X X Solution container, metering unit and hose Visual inspection (condition, leaks) - SR 450 Clean X X Strainer in container Clean or replace Metering unit on blower tube Check 36 X X X X X X X X X X X X X X X X SR 430, SR 450