Bernina 810 Manual - Page 52

avoid, breakdowns

|

View all Bernina 810 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 52 highlights

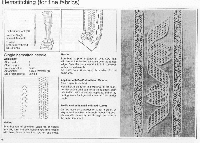

How to avoid breakdowns 1. Generally, most breakdowns are ishing (call authorized Bernina dealer When you bring your machine to an ex- caused by incorrect handling of the to change needle plate). pert, please take along accessories machine. If breakdowns do occur then and foot starter. examine whether: 4. Faulty stitches. Can have the follow- a) the needle is inserted properly (the ing causes: flat side of the needle must be al the a) wrong needle. Use system 705 B only; back); b) needle is crooked or not inserted b) the correct needle is being used correctly (push needle right up in the (see needle and thread table); needle bar!); c) the machine is cleaned properly. c) low quality needle, roughly polished. Lift free arm cover plate and remove sewing lint; 5. Needle breaks. Can have the follow- d) the hook race is clean and oiled: ing causes: 0) there are pieces of thread caught a) needle clamp screw Is not suffi- between the thread tension discs or ciently tightened; under the bobbin case spring: b) the material was withdrawn towards f) hand wheel is secured properly. the operator and needle bent (material should always be withrawn to the rear): 2. If the upper thread breaks. Can have c) when sewing over thick part mate- the following causes: rial was pushed whilst the needle was a) top thread is too tight; still in, therefore it bent, touched the b) use of inferior needles (buy them throat plate and broke. preferably from a Bernina dealer); d) when cheap cotton, irregularly twist- c) needle inserted wrongly. Flat side ed or even containing knots is used. must be at the back; d) the needle is blunt or crooked; e) poor quality or knotted thread. 6. Seam irregularities. A bad uneven seam results: Thread has dried out due to long a) if thread remnants are between the storage; thread tension discs; f) the needle plate hole is pitted by b) if thread remnants are under the needle and needs repolishing (bring bobbin case tension spring. free arm cover plate. resp needle plate to authorized Bernina dealer). 7. Machine runs slowly g) hook point is damaged (call authoriz- a) Motor does not function properly ed Bernina dealer). (call authorized Bernina dealer); h) foot starter does not function prop- 3. If bottom thread breaks. Can have erly (call authorized Bernina dealer); the following causes. c) use of low quality oil can block the a) the bottom thread tension is too tight: movement. The machine must be dis- b) bobbin is crushed and jammed in mantled and cleaned. Call Bernina the bobbin case; dealer; c) needle hole in throat plate is dam- d) machine has been standing in a aged by the needle and needs repol- cold room. 61