Brother International EF4-B561 Service Manual

Brother International EF4-B561 Manual

|

View all Brother International EF4-B561 manuals

Add to My Manuals

Save this manual to your list of manuals |

Brother International EF4-B561 manual content summary:

- Brother International EF4-B561 | Service Manual - Page 1

SERVICE MANUAL FOR BROTHER MODEL EF4-B561, 571 MA4-B581 BROTHER INDUSTRIES, LTD., NAGOYA, JAPAN. - Brother International EF4-B561 | Service Manual - Page 2

AND DIFFERENTIAL FEED ADJUSTMENT 27 7. SEWING INSTRUCTION 28 M Single needle two thread 28 W Single needle three thread 29 ❑3 Twin needle four thread 31 W Twin needle five thread 31 8. TROUBLE SHOOTING 32 EHIDEI7REE Thread breakage (Overlock Stitch Needle) 32 Thread breakage (Looper - Brother International EF4-B561 | Service Manual - Page 3

1. FEATURES 1. These models have the same sewing performance as the high-speed types (Models EF4-B511, B531 and MA4-B55I) so they can be used for normal stitching, ruffling, parts, attachments and other devices of these models are interchangeable with those of Models EF4-B511, B531 and MA4-B551. - Brother International EF4-B561 | Service Manual - Page 4

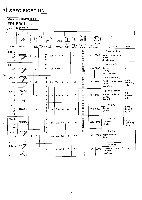

2. SPECIFICATION BROTHER INDUSTRIES LTD. EF4-B561 MADE IN JAPAN Z ry"t, qub 'class Na. Stitch form 0 --1'.;:z 0cc) Maximo Needle No. of ;ihlor: c/ gurngle stitch l,e,,ng, th (mm( feed redo (a) m .-r-, (b) 0 olfught Pitch presser - Brother International EF4-B561 | Service Manual - Page 5

SPECIFICATION (9) BROTHEP INDUSTRIES LTD. EF4-B561- MADE IN JAPAN ,- , 77r- ' Subclass No. Stitch form No. of needle If ni .>z, , ,..s, .,_.:. - Brother International EF4-B561 | Service Manual - Page 6

SPECIFICATION #.* BROTHER INDUSTRIES LTD. EF4-B571- MADE IN JAPAN ri -olass 021-4 -5 - Stfloh for', m..ximum ‹ /4-, pc) l i'''-g (a) 9 Needle No of No of o Bight rggit'h needle thread (trim) Imm) Own) Differential feed - Brother International EF4-B561 | Service Manual - Page 7

SPECIFICATION BROTHER INDUSTRIES LTD. EF4-B571- MADE IN JAPAN , , Sub-class Stitch form 033-5 34'-\\' 6 3.6 0.3-.1.8 6 1.6 / 7 Thin, medium taping li #11 5000 Knitted underwear -Tape- 0 shirts. guide Tee shirts 042-5 -6 -7 5 Thin, medium taping k. 2 4 2.2 6 3.6 0.3-1.8 6 1.6 III - Brother International EF4-B561 | Service Manual - Page 8

SPECIFICATION BROTHER INDUSTRIES LTD MA4-B581- MADE IN JAPAN I Sub-claas No. 061-2 - -43 -5 Stitch fonts - - -(--1.;/' CDC) No. of needle Mammon. Needle stitch No. of gauge Sight length thread - Brother International EF4-B561 | Service Manual - Page 9

SPECIFICATION BROTHER INDUSTRIES LTD. MA4-B581- MADE IN JAPAN --E I SubcleM No. Stitch form 4 1.6 5 3 2 4 2 4 3.6 0.3-1.8 4 1.6 5 Thin, medium taping E #11 5000 Knitted underwear •Tape- Shirts guide Tee shirts, pajamas 0 Thin, medium taping E #11 5000 Knitted underwear -Tape- Shirts - Brother International EF4-B561 | Service Manual - Page 10

SPECIFICATION BROTHER INDUSTRIES LTD. MA4-B581- MADE IN JAPAN z, SO•clus No. Stitch form 081-3 7'7'7" 1 4 -5 082-3 4 / -5 § taping 2 4 5 6 3.6 0.3-1.8 6 1.6 tit. #16 5000 Knitted underwear •Tape- Shirts guide 7 hi Tee shirts, pajamas 087-5 _6 .4.24: * 088-5 -6 * 5 Extra heavy 2 - Brother International EF4-B561 | Service Manual - Page 11

into the top of needle bar crank shaft and gets up and down movement. m • Needle bar rji that is held by needle bar clamp Q is guided by needle bar bushing lower ® upper and needle bar bushing 2 UNDER LOOPER MECHANISM El OVER LOOPER MECHANISM 0 • In case that crank shaft 0 may rotate to - Brother International EF4-B561 | Service Manual - Page 12

DOUBLE CHAIN STITCH LOOPER MECHANISM OO O 0 OO Os OO O0 12 Id 1) Double chain stitch looper back and forth movement mechanism In case that crank shaft may rotate to the direction indicated with arrow, with longitudinal eccentric cam 0, longitudinal feed driving rod 0 moves up and down. IC - Brother International EF4-B561 | Service Manual - Page 13

pressure of lower . knife holder spring plays a role of edge trimming with upper knife 0. And lower knife holder guide plays role of positioning of lower knife @ and guide of lower knife holder A FEED MECHANISM ti C5) 0 I © 1) Horizontal feed mechanism In case that crank shaft @ may rotate - Brother International EF4-B561 | Service Manual - Page 14

down, presser foot supporter (0 is lowered with spring hook Q. • Main presser arm connected with pin 0 is raised with presser foot supporter 0. • If presser 2 Remove needles 0. 2 3 Remove cloth plate 0. 2 4 Remove cloth guide (L) O. 2 0190 10 Q'ty of screw 5 Open feed mechanism cover (B) - Brother International EF4-B561 | Service Manual - Page 15

knife 49. S. 3 Remove upper knife holder O. 4 Remove nut 1 5 Remove lower knife as holding it by hand. 1 Q'ty of screw 6 Remove lower knife holder guide 0. 2 7 Remove lower knife holder 9 as holding it by hand. (Pull out spring for lower knife holder 1 also.) 8 Remove lower knife holder - Brother International EF4-B561 | Service Manual - Page 16

Q. 1 4 Remove under looper holder 0. 1 5 Remove over looper thread take-up (R) Q and under looper thread take-up (R) Q 1 6 Remove under looper thread guide O. 1 Th ED r•• Procedures 1 Remove inside cover 0. (Set over looper 0 to the left mostly.) 2 Remove over looper 0. Q'ty of screw - Brother International EF4-B561 | Service Manual - Page 17

CV 2 O - • Procedures Q'ty of screw 1 Remove needle thread take-up 0. 1 2 Remove needle thread guide (A) Q. 1 3 Remove needle thread take-up supporter 0. 1 4 Remove chain stitch needle thread guide 0 (B581). 1 5 Remove face plate 0. 4 (Stopper spring fp is naturally to be removed out - Brother International EF4-B561 | Service Manual - Page 18

body firmly putting of face plate (1) lightly, then 7 take care not make any clearance. 5 Install needle thread take-up supporter 0 to needle bar clamp O. 1 6 Install needle thread guide (A) 0 to face plate 0. 1 Q'ty of screw 7 Install needle thread take-up 0 to needle thread 1 take-up - Brother International EF4-B561 | Service Manual - Page 19

Procedures Q'ty of screw 8 Insert needles all the way into needle clamp Q and tighten screws. 9 Install needle plate ® . 2 10 Check part ® on the over looper driving lever and see whether the machine is for standard use (S) or high-lift use (H). 11 Standard needle for adjustment is as - Brother International EF4-B561 | Service Manual - Page 20

2 UNDER LOOPER MECHANISM C2) Procedures Q'ty of screw 1 Remove needles and needle plate. 2 Temporarily fasten under looper holder 0 on under 1 looper lever shaft 0. 3 Insert under looper Q all the way into under looper holder 0. 4 Measure under looper 0 tilt at its point and bottom, adjust - Brother International EF4-B561 | Service Manual - Page 21

assembly 0 onto flame (0 and over looper driving lever onto over looper lever shaft 0 at the same time. 2 Temporarily fasten over looper holder guide assembly 0. 3 3 Move the over looper driving lever 0 up or down until there is the least resistance so over looper driving lever is in alignment - Brother International EF4-B561 | Service Manual - Page 22

Procedures Meeting point O 0 0 B A A: Distance between over looper point and needle center when over looper point is at needle plate top. B: Distance between over looper point and needle center when over looper is at left extremity. Single needle (two threads) Over spreader Q for two threads is - Brother International EF4-B561 | Service Manual - Page 23

to that 1 of (B) 0 in order to make clearance about 0.3 to 0.5 mm. 7 Temporarily fasten double chain stitch needle guard (B) to needle plate support bracket. 0 .3-0 .5mm---iAix Standard specifications 1.5 mm High-lift specification 1.2 mm 0 -0 05mm CD C) 8 Match the looper point with the needle - Brother International EF4-B561 | Service Manual - Page 24

Procedures Q'ty of screw 1 Temporarily fasten lower knife holder support 0 on 2 needle plate support bracket 0. 2 Temporarily fasten lower knife holder guide 4) on needle 2 plate support bracket 0. 3 Insert spring 0 into lower knife holder 0, fit lower 1 knife holder into lower knife holder - Brother International EF4-B561 | Service Manual - Page 25

thread can be sharply cut. Thread a FEED AND PRESSER FOOT MECHANISM Cl) e e (B561, B571) (B581) Procedures Q'ty of screw I Remove needle plate. 2 2 Adjust differential feed bar Q. 1 5 Install needle plate on needle plate support bracket. 2 6 Turn the pulley until feed dogs are raised - Brother International EF4-B561 | Service Manual - Page 26

-up (R) ID and under looper thread take-up (R) Q to over looper lever 1 shaft O. 3 Install under looper thread guide to thread guide support O. 4 Adjust each thread take-up and thread guide to their standard positions as shown above after raising the needle up highest. * When looper thread take - Brother International EF4-B561 | Service Manual - Page 27

advanced (counterclockwise), the looper thread tension increases; and when it is moved back (clockwise), the looper thread tension decreases. 7 Install thread guide (R) 0 and (L) Q on thread take- 2 up bracket (0, making sure that they are equidistant from the reference line on thread take-up holder - Brother International EF4-B561 | Service Manual - Page 28

about 0.5 mm O e 0 Procedures Q'ty of screw 1 Temporarily fasten front cover supporter 0 on machine body. 2 2 Temporarily fasten front cover 0 on oil reservoir. (Close front cover) 2 3 Temporarily fasten front cover guide 0 parallel to machine body. 2 0, * Make an adjustment so that, when - Brother International EF4-B561 | Service Manual - Page 29

6. STITCH LENGTH AND DIFFERENTIAL FEED ADJUSTMENTS EI STITCH LENGTH ADJUSTMENT A desired stitch length can be selected by means of the scale on math feed arm 0 and the numerals on the scales of main feed arm and differential feed arm indicate stitch length in millimeters, but actual stitch length - Brother International EF4-B561 | Service Manual - Page 30

. Feed arm Specificstions Normal stitching Denim Ruffler Bulky Main feed arm Differential feed arm 3.6mm 3.3mm 2.5mm 6.5mm 9.0mm 9.0mm 7. SEWING INSTRUCTION SINGLE-NEELDE, TWO-THREAD * Thread tension means the tension of the thread pulled in the running direction after the tension disc. No - Brother International EF4-B561 | Service Manual - Page 31

- Looper thread „L --- - Looper thread Needle thread - Needle thread Even if wooly nylon thread is used as needle thread, there will be no skipped stitches because the thread tension is small. SINGLE-NEEDLE, THREE-THREAD No. Cloth Thread 1 Knit under wear material 2 n Cotton #6012 - Brother International EF4-B561 | Service Manual - Page 32

by lower the over looper and under looper thread take-up (R). Th I ( Lower 0 on Pass the thread through the two holes in the thread guide without winding. O If stitches skip (Needle and under looper): 1) Use a DC X27 needle. 2) Make an adjustment by only slightly bending the needle. Make under - Brother International EF4-B561 | Service Manual - Page 33

thread tends to break. In that case, do not tighten the needle thread tension but adjust the positions of the thread take-up and thread guide if the thread tension must be increased. Note on Item 2: About the same tension may be used for sewing with synthetic and cotton threads. Note - Brother International EF4-B561 | Service Manual - Page 34

screw threads). Use gauge parts for denim specification. 8. TROUBLE SHOOTING ❑1 THREAD BREAKAGE (Overlock Stitch Needle) CHECK POINT 1 Wrong threading. - 2 . Change needle for a good one. Adjust to proper position. Change thread guide for a new one. Change it for a new one or smooth surface with - Brother International EF4-B561 | Service Manual - Page 35

pressure. 31 Use thread of good quality. Change needle for a good one. Adjust to proper position. 16 Adjust to proper position. 25 Change thread guide for a new one. Change it for a new one or smooth surface 20 with oil stone or buff. Blunt Flaws Adjust to proper clearance between - Brother International EF4-B561 | Service Manual - Page 36

Da SKIP STITCHING (Overlock Stitch) CHECK POINT ADJUSTMENT PAGE 1 Wrong threading. Refer to threading diagram. 2 Excessive pressure of tension disc. Adjust to proper pressure. 28 In case skipping between - Brother International EF4-B561 | Service Manual - Page 37

• SKIP STITCHING (Double Chain Stitch) CHECK POINT ADJUSTMENT 1 Wrong threading. Refer to threading diagram. 2 Excessive pressure of tension disc. Adjust to proper pressure. 3 Wrong position of looper thread take-up. 1 • In case of skipping on rightward movement of looper. 1 Large clearance - Brother International EF4-B561 | Service Manual - Page 38

. -.. Change it for more large one. -•-• Adjust to proper pressure. -. Adjust to proper position. PAGE 28 24 • 25 WRONG CHAINING-OFF (Overlock Stitch) CHECK POINT 1 Wrong threading. 4 2 Excessive pressure of tension disc. 1 3 Too weak pressure of tension disc. 1 4 Wrong position of looper thead - Brother International EF4-B561 | Service Manual - Page 39

threading diagram. Adjust to proper pressure. 3 Too weak pressure of tension disc. --. Adjust to proper pressure. 4 Wrong position of needle thread guide. - Adjust to proper position. 5 Wrong position of looper thread take-up. -.- Adjust to proper position. 6 Wrong installment of main feed

SERVICE

MANUAL

FOR

BROTHER

MODEL

EF4-B561,

571

MA4-B581

BROTHER

INDUSTRIES,

LTD.,

NAGOYA,

JAPAN.