Craftsman 3800 Operation Manual - Page 19

Spark Arrester Service, Sediment Cup Cleaning

|

View all Craftsman 3800 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

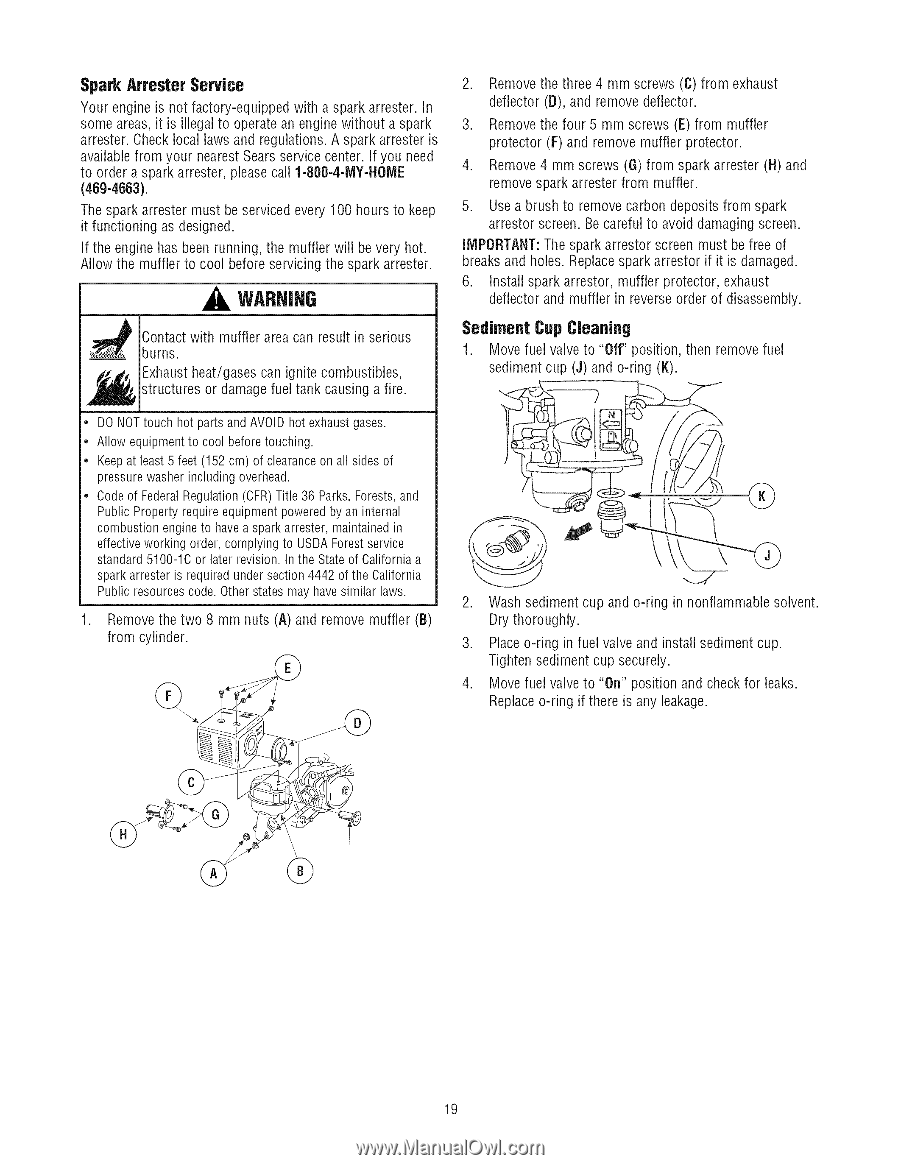

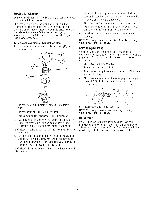

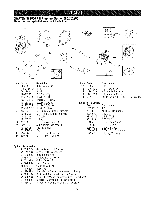

Spark Arrester Service Your engine is not factory-equipped with a spark arrester. In some areas, it is illegal to operate an engine without a spark arrester. Checklocal laws and regulations. A spark arrester is availablefrom your nearest Sears service center. If you need to order a spark arrester, please call 1-SOO-4-MY-HOIVlE (469-4663). The spark arrester must be serviced every 100 hours to keep it functioning as designed. If the engine has been running, the muffler will be very hot. Allow the muffler to cool before servicing the spark arrester. WARHIHG s_ Cbuornntsa.ct with muffler area can result in serious _ sEtrxuhcatuusrethseoart/dgaamseasgceafuneigl tnaitnekccoamusbiunsgtiablfeirse,. . DONOTtouch hot partsandAVOIDhot exhaustgases. * Allowequipmento cool beforetouching. . Keepat least5 feet (152cm) of clearanceon all sidesof pressurewasherincludingoverhead. * Codeof FederaRl egulation(CFR)Title 36 Parks,Forestsa, nd PublicPropertyrequireequipmentpoweredby an internal combustionengineto havea sparkarrester,maintainedin effectiveworkingorder,complyingto USDAForestservice standard5100-1Cor later revision.In the Stateof Californiaa sparkarresteris requiredundersection4442 of the California Publicresourcescode.Otherstatesmay havesimilar laws. 1. Removethe two 8 mm nuts (A) and remove muffler (B) from cylinder. 2. Removethe three 4 mm screws (C) from exhaust deflector (D), and remove deflector. 3. Removethe four 5 mm screws (E) from muffler protector (F) and remove muffler protector. 4. Remove 4 mm screws (G) from spark arrester (H) and remove spark arrester from muffler. 5. Use a brush to remove carbon deposits from spark arrestor screen. Be careful to avoid damaging screen. IMPORTANT:The spark arrestor screen must be free of breaks and holes. Replacespark arrestor if it is damaged. 6. Install spark arrestor, muffler protector, exhaust deflector and muffler in reverse order of disassembly. Sediment Cup Cleaning 1. Move fuel valve to "Off" position, then remove fuel sediment cup (J) and o-fin((K). , Wash sediment cup and o-ring in nonflammable solvent. Dry thoroughly. 3. Place o-ring in fuel valve and install sediment cup. Tighten sediment cup securely. 4. Move fuel valve to "On" position and check for leaks. Replace o-ring if there is any leakage. 19