Craftsman 79194 Operation Manual - Page 9

Linereplacement - the

|

View all Craftsman 79194 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

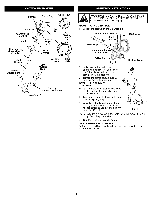

LINEREPLACEMENT for Hassle-Free TM Cutting Head I blade assembly. Excessive line length will make the WARNING: Do not remove or alter the line cutting I oruCtchdamageOtVherThheuant.imt.osay ead to serous persona n ury Always use Craftsman® Hassle-Free TM XTRA QUIET Spiral Line. Choose the line size best suited for the job at hand. Red colored line is designed for cutting grass and small weeds. Black colored line is designed for cutting larger weeds and light brush. NOTE: Before inserting new line into the holes in the cutting head, identify the proper holes. Follow directions as shown on the line glide plate. Do Not attempt to remove the cutting head from the unit when replacing line. 1. Remove the old line and line glide plate from the cutting head. 2. Clean entire surface of cut-ting CHutetiandg head. Note positions "A" and "B" on the cutting head. LinPelaGtelide Arrow 3. Reinstall line glide plate (Fig. 15). Align arrow with: "A" when using medium (red) or large (black) line, or "B" when using lines with diameters smaller than medium (red) line NOTE: Line glide plate must be reinstalled inserting new line. Fig. 15 in cutting head before 4. Insert both ends of your line through the proper holes in the side of the cutting head (Fig. 16). 5. Pull the line and make sure the line is against the hub and is fully extended through the positioning tunnels (Fig. 17). Positioning Tunnel 6. Correctly installed line will be the same length on both sides. NOTE: Do not rest the Hassle- FreeTM Cutting Head on the ground while the unit is running. Some line breakage will occur from: Fig. 16 Line against the hub _Positioning Tunnel • Entanglement with foreign matter Fig. 17 • Normal line fatigue • Attempting to cut thick, stalky weeds • Forcing the line into objects such as walls or fence posts • MAINTENANCE SCHEDULE • maintenance or repairs with unit running. Always WseArvRicNeINaGn:d reTpoairpraevceonotl suenritio. uDsiscinojunrnye,cnt evtheer sppearfrokrm plug wire to ensure that the unit cannot start. Perform these required maintenance procedures at the frequency stated in the table. These procedures should also be a part of any seasonal tune-up. NOTE: Some maintenance procedures may require special tools or skills. If you are unsure about these procedures take your unit to a Sears or other qualified service dealer. NOTE: Maintenance, replacement, or repair of the emission control devices and system may be performed by a Sears or other qualified service dealer. In order to assure peak performance of your engine, inspection of the engine exhaust port may be necessary after 50 hours of operation. If you notice lost RPM, poor performance or general lack of acceleration, this service may be required. If you feel your engine is in need of this inspection, refer service to a Sears or other qualified service dealer for repair. DO NOT attempt to perform this process yourself as engine damage may result from contaminants involved in the cleaning process for the port. FREQUENCY Before starting engine Every 10 hours 1st change at 10 hours At 25 hours/every 25 hours Every 50 hours 10 hours on new engine Every 25 hours Every 25 hours MAINTENANCE REQUIRED Fill fuel tank with fresh fuel Check oil Clean and re-oil air filter Change oil Change oil Clean spark arrestor Check rocker arm to valve clearance and adjust Check rocker arm to valve clearance and adjust Check spark plug condition and gap SEE p. 6 p. 10 p. 11 p. 10 p. 10 p. 13 p. 12 p. 12 p. 12